How Can End-of-Life Tires Be Efficiently Converted into Recycled Rubber Resources?

When the disposal of end-of-life tires shifts from “simple landfilling” to “high-efficiency resource utilization,” the Automatic Extrusion-Type Tyre Recycling System has emerged as the new industry core. It can complete tire crushing, steel wire separation, fiber collection, and rubber powder production in one stop at room temperature—generating no wastewater, waste gas, or dust while producing high-value recycled rubber products. Today, we break down the technical logic, process details, and industrial value of this system.

What is the Automatic Extrusion-Type Tyre Recycling System?

The Automatic Extrusion-Type Tyre Recycling System is a continuous production line based on “room-temperature physical processing.” Its core relies on coordinated processes of extrusion, shearing, and grinding to convert end-of-life tires (a composite structure of rubber, steel wire, and fiber) into:

- Fine rubber powder with a particle size of less than 30 mesh (customizable to 20–120 mesh as needed);

- Steel wire raw material with a purity of over 96%;

- Recyclable fiber impurities.

The system’s key advantage lies in its “integrated operation”: no phased processing is required—only one production line is needed to turn a complete tire into finished rubber powder. The entire process produces no secondary pollution, and the resulting rubber powder can directly replace natural rubber for the production of thousands of rubber products.

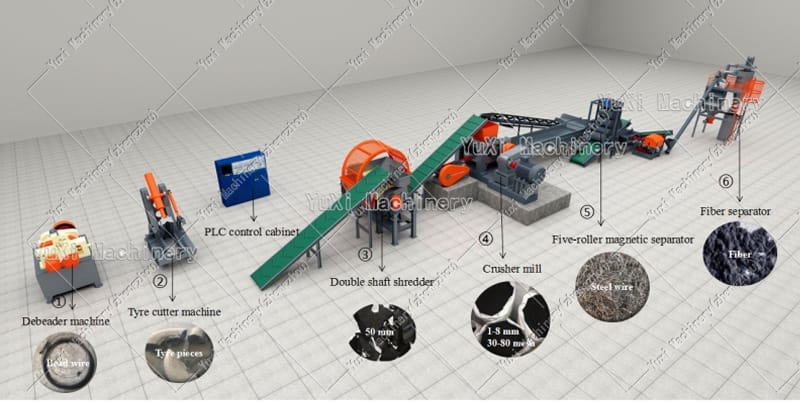

Full Process of the Automatic Extrusion-Type Tyre Recycling System: Efficient Collaboration of 7 Core Steps

Taking an industrial production line as an example, the complete process of this system includes 7 core links, enabling seamless connection from “tire to finished product”:

- Bead Breaker: Separate Tire Bead Steel Wire

The first step for end-of-life tires entering the production line is to be fixed by the hydraulic clamp of the bead breaker. A rotating cutter cuts the connection between the bead and the tire body, separating the bead and its internal steel wire intact. This step avoids bead wear on subsequent equipment while enabling initial steel wire recovery. - Tire Cutter: Pre-cut the Tire Body into Sections

After bead removal, the tire body enters the tire cutter, where hydraulic-driven blades cut it into 2–3 rubber blanks. Pre-sectioning improves the efficiency of subsequent crushing by ensuring more uniform force distribution on the rubber. - Primary Crusher: Initial Crushing of the Tire Body into Rubber Blocks

Rubber blanks enter the primary crusher and are crushed into approximately 5 cm rubber blocks via the engagement of “twin-shaft extrusion rollers.” This “extrusion crushing” step initially loosens the fibers and steel wire inside the rubber, preparing it for subsequent fine processing. - Twin-Roll Crusher: Refine Rubber Blocks into Granules/Coarse Powder

When 5 cm rubber blocks enter the twin-roll crusher, high-hardness tooth rollers shear and grind them into two products:

1–6 mm rubber granules;

10–80 mesh coarse rubber powder.

→ The gap between the twin rolls can be adjusted as needed to flexibly control the particle size of the output. - Five-Roll Magnetic Separator: High-Precision Steel Wire Separation

As mixed materials pass through the five-roll magnetic separator, rollers with gradually increasing magnetic field strength can adsorb over 96% of steel wire debris. Compared to traditional single-roll magnetic separation, the five-roll structure more thoroughly separates fine steel wire embedded in the rubber, ensuring the purity of subsequent rubber products. - Fiber Collection System: Separate and Recover Fiber Impurities

After magnetic separation, rubber materials enter the fiber collection system. A combination of “airflow screening + vibration filtration” separates and concentrates residual fiber impurities from the rubber—these fibers can be reused as filler. - Rubber Grinder: Fine Processing of Finished Rubber Powder

Finally, rubber granules/coarse powder enter the rubber grinder, where high-speed rotating grinding discs further grind them into 20–120 mesh finished rubber powder. The grinder is equipped with a water cooling system to control processing temperature and prevent rubber aging due to high heat.

Outputs of the Automatic Extrusion-Type Tyre Recycling System: High-Value Applications Across Multiple Scenarios

The system’s outputs are not a single product but “graded resources” covering different particle sizes, adapting to needs across multiple fields:

- 50 mm rubber blocks: Can be sold to cement plants, paper mills, or power plants as a coal substitute for fuel, balancing environmental protection and cost;

- 1–6 mm rubber granules: Used to produce rubber floor tiles, mats, or to pave elastic surfaces in parks and kindergartens (excellent shock absorption and anti-fall performance);

- 20–120 mesh rubber powder: Can be directly used in manufacturing new tires, road asphalt paving, or processed into end products such as shoe insoles and sealing fillers.

Core Advantages of the Automatic Extrusion-Type Tyre Recycling System: Dual Guarantee of Equipment and Performance

This system has become the industrial first choice thanks to four highlights in equipment design and performance:

- Wear-Resistant Rollers: Core rollers are made of chilled cast iron, offering strong wear resistance and significantly extending service life;

- Convenient Gap Adjustment: The rear roller is equipped with a turbine adjustment device—simply rotating the turbine adjusts the roller gap to adapt to different particle size requirements;

- High-Strength Twin-Roll Material: Key twin-roll components are made of cast steel, capable of withstanding heavy loads of extrusion and shearing for continuous heavy-duty operation;

- Long-Lasting Water Cooling System: An independent water cooling system reduces the operating temperature of core components (e.g., gearboxes), extending the overall service life of the equipment.

Conclusion: Industrial Value of the Automatic Extrusion-Type Tyre Recycling System

From “end-of-life tires” to “multi-category recycled resources,” the Automatic Extrusion-Type Tyre Recycling System achieves breakthroughs in three dimensions:

- Environmental Dimension: It completely solves the “black pollution” problem of end-of-life tires—processing 1 ton of tires reduces solid waste by approximately 0.8 tons;

- Efficiency Dimension: The integrated production line transforms processing from “phased” to “continuous,” with a single line capable of handling dozens of tons per day;

- Economic Dimension: Outputs such as rubber powder and granules can directly connect to downstream industries, forming a closed-loop value chain of “recycling-processing-application.”

As global tire scrappage volumes continue to grow, this system is becoming a typical carrier of the “circular economy”—it is not just a piece of equipment, but an industrial bridge connecting “waste” and “new resources.”