How Does an Automatic Tire Recycling System Optimize Efficiency and Costs in Waste Tire Processing?

A deep dive into the full-process intelligent architecture, core technology modules, and industrial value of automatic tire recycling systems—revealing how automation and digitization drive efficiency gains and cost reductions in waste tire handling.

Global annual waste tire generation exceeds 1.5 billion units. Traditional recycling models, which rely on manual labor, suffer from low efficiency, high costs, and inconsistent product purity. The emergence of automatic tire recycling systems—built on an architecture of “intelligent production lines + digital management + fully unmanned workflows”—has transformed waste tire processing from labor-intensive to technology-intensive. This shift delivers industry-leading improvements: 40% higher processing efficiency, 60% lower labor costs, and consistently 99.8% pure end products. This article breaks down the industrial logic of this intelligent system across four dimensions: system architecture, core technologies, application scenarios, and industrial value.

I. Intelligent Architecture of Automatic Tire Recycling Systems: A Fully Unmanned Closed-Loop Workflow

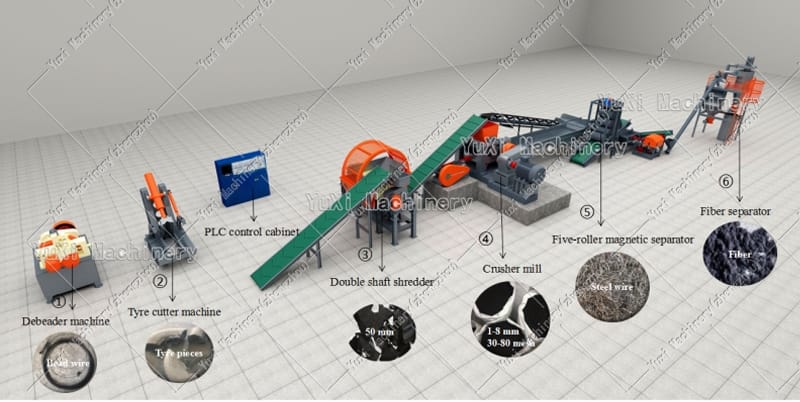

The core of an automatic tire recycling system is a fully unmanned closed loop encompassing “intelligent loading → automated processing → digital sorting → customized finished products.” Its architecture consists of 5 core modules, interconnected and coordinated via industrial internet for data sharing:

Intelligent Loading and Pretreatment Module

- AGV Automated Loading Unit: Uses laser navigation to transport waste tires from storage to the production line entrance. Equipped with a visual recognition system, it automatically classifies tire types (passenger, truck, or construction) and matches corresponding processing parameters.

- CNC Automatic Bead Cutting Unit: Servo-driven blades adjust cutting paths based on tire specifications to precisely separate bead wires (with ≤0.5mm separation error). Wires are automatically conveyed to a metal recovery bin, enabling “zero manual intervention” in pretreatment.

Automated Multi-Stage Shredding Module

This module is the system’s processing core, using an intelligently linked shredding unit cluster to refine materials incrementally:

- Primary Intelligent Shredder: Features pressure sensors and a variable-frequency drive system that adjusts shearing force based on tire hardness (120kN for passenger tires; 200kN for truck tires). It cuts tires into 5–10cm rubber blocks, while an in-line particle size detection system screens for qualified materials.

- Secondary/Tertiary Automatic Grinding Units: Combine “roller milling + airflow classification.” Roller gaps are adjusted in real time (±0.01mm precision) via servo motors to refine blocks into 1–3mm granules. A temperature sensor (controlling ≤55°C) and vibration monitoring system work together to prevent equipment overload or rubber aging.

Digital Multi-Phase Sorting Module

This “intelligent hub” ensures product purity, using a multi-sensor fusion sorting system to separate rubber, steel, and fiber:

- High-Resolution Visual Sorting Unit: Uses 3D line-scan cameras + AI recognition algorithms to identify fiber impurities (≤0.1mm detection precision) in granules. Pneumatic sorting valves enable millisecond-level separation.

- Intelligent Magnetic Separation Unit: Adjusts magnetic field strength (1.4–1.6T) based on material flow, coordinated with belt speed control (0.8–1.2m/s), achieving 99.5% efficiency in separating capillary steel fibers.

- Eddy Current Sorting Unit: Uses real-time conductivity detection to distinguish rubber from metal shavings, with ≥99.8% sorting accuracy. Results are synced to the digital management platform.

Customized Finished Product Processing Module

This module enables flexible, order-driven production:

- Intelligent Screening Unit: Equipped with a multi-channel vibrating screen and automatic screen-changing system, it switches screens based on downstream order requirements (e.g., 40-mesh powder for modified asphalt; 120-mesh powder for rubber products) with an 8t/h screening efficiency.

- Automatic Packaging Unit: Links load cells with vacuum packaging machines to enable quantitative bagging (≤50g error), labeling, and palletizing. Finished products are then automatically transported to storage by AGVs.

Digital Management and Maintenance Module

This “brain” of the system enables full-process visualization, traceability, and optimization via an industrial internet platform:

- Real-Time Data Monitoring Interface: Displays processing volume, energy consumption, and equipment status (e.g., roller temperature, motor current) for each unit. Abnormalities trigger automatic audio-visual alarms and shutdown protection.

- Predictive Maintenance System: Uses algorithms to forecast equipment failure risks (72-hour advance warning) based on operational data (e.g., bearing vibration, motor temperature rise), reducing unplanned downtime.

- Automatic Production Reporting: Generates daily/weekly/monthly reports linking processing volume, energy consumption, and product purity to support production line optimization.

II. Core Technologies of Automatic Tire Recycling Systems: The Foundation of Intelligence

The system’s automation and intelligence rely on the deep integration of three core technologies:

Multi-Sensor Fusion Recognition Technology

- Visual Recognition: Uses 20-megapixel line-scan cameras + deep learning algorithms to detect tire types, material impurities, and finished product particle sizes in real time (200 frames/second).

- Multi-Physical Quantity Sensing: Integrates 12 sensor types (pressure, temperature, vibration, conductivity, etc.), with data collection frequencies of 10Hz per device to provide precise input for intelligent control.

Industrial Internet and Collaborative Control Technology

- PLC + SCADA Collaborative Architecture: Uses a Siemens S7-1500 PLC for real-time equipment-level control and a SCADA system for production line-level scheduling, with ≤10ms data transmission latency.

- Edge Computing Nodes: Deployed at critical production line units, enabling a hybrid “local data processing + cloud backup” architecture to avoid production disruptions from network fluctuations.

Flexible Production Technology

- Adaptive Parameter Adjustment: Automatically matches shredding force, grinding gaps, and sorting parameters based on tire specifications and hardness, enabling “one production line for multiple material types.”

- Order-Driven Production: Integrates with downstream order systems via MES to adjust finished product specifications (mesh size, packaging volume), supporting “small-batch, multi-variety” flexible output.

III. Application Scenarios of Automatic Tire Recycling Systems: From Single Processing to Cross-Industry Linkage

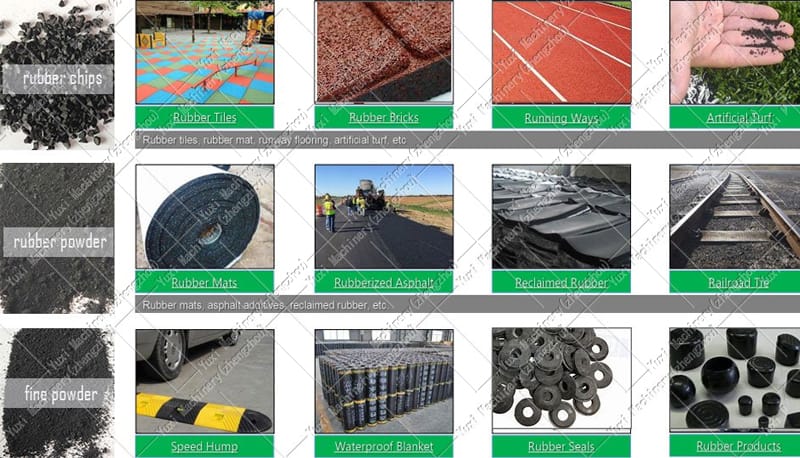

The value of automatic tire recycling systems extends beyond “processing waste tires”—their consistently high-quality finished products link multiple industries to form a “recycle-process-apply” industrial closed loop:

- Infrastructure: Large-Scale Supply of Modified Asphalt

The system’s 40–80 mesh rubber powder (≥99.8% stable purity) serves as a core raw material for modified asphalt. For EU road construction, this powder improves pavement rut resistance by 50% and supply stability by 30% (vs. traditional recycling), making it a designated material for Europe’s top 3 asphalt manufacturers. - Recycled Rubber Products: Supply of High-End Circular Materials

120–200 mesh fine rubber powder (maintained elasticity via the system’s low-temperature grinding, with ≤3 Mooney viscosity fluctuation) can be blended with virgin rubber to produce high-end products (e.g., tire sidewalls, seals). Michelin, Goodyear, and others have integrated this powder into their supply chains, increasing recycled rubber content in products from 10% to 25%. - Solid Waste Processing Parks: Intelligent Processing Units

Automatic tire recycling systems act as standardized units in solid waste processing parks, linking with plastic and metal recycling lines. For example, the Eindhoven (Netherlands) waste park uses 3 systems to process 120,000 tons of waste tires annually, supplying rubber powder, steel, and fiber to the park—boosting overall park revenue by 25%. - Regional Recycling Centers: Distributed Processing Networks

The system’s modular design adapts to recycling centers of all sizes:

Small Centers (10 tons/day): Deploy 1 compact automated line to meet county-level recycling needs.

Large Centers (50 tons/day): Deploy 2–3 linked lines to serve municipal-level waste tire processing while supplying recycled materials to surrounding industries.

IV. Industrial Value of Automatic Tire Recycling Systems: Triple Upgrades in Efficiency, Cost, and Ecology

Compared to traditional models, the industrial value of automatic tire recycling systems spans three dimensions:

Quantifiable Efficiency and Cost Upgrades

- Processing Efficiency: Single lines handle 20–50 tons/day (vs. 12–25 tons/day for traditional systems), a 40%+ improvement.

- Labor Costs: Single lines require only 1 operator (vs. 6–8 for traditional systems), a 60% reduction.

- Energy Costs: Intelligent linked control reduces unit processing energy consumption to 120kWh/ton (vs. 180kWh/ton for traditional systems), a 33% reduction.

Stable Breakthroughs in Product Quality

Traditional rubber powder purity fluctuates between 95–98%, but automatic systems achieve ≥99.8% stable purity and ≤0.1 mesh particle size deviation via full-process intelligent control. This stability enables entry into high-end applications (e.g., new energy battery materials), increasing product premiums by 30%.

Synergistic Ecological and Industrial Value

- Ecological Benefits: The system meets the EU’s highest industrial environmental standard (EMAS certification) with ≤5mg/m³ dust emissions and ≤75dB noise, avoiding secondary pollution from traditional processing.

- Industrial Linkage: Stable recycled material supply drives the formation of a “waste tire → recycled rubber powder → infrastructure/rubber products” circular chain, increasing waste tire resource utilization rates from 80% to 95%.

V. Industry Trends: The Future of Automatic Tire Recycling Systems

Automatic tire recycling systems are evolving toward “greater intelligence, flexibility, and connectivity”:

- Deep AI Optimization: Machine learning algorithms analyze production line data to automatically optimize shredding force and grinding gaps, balancing processing efficiency and product quality.

- Carbon Neutrality Adaptation: Integrating photovoltaic power and waste heat recovery systems reduces line energy consumption by 20%, enabling “carbon-neutral processing” for recycling enterprises.

- Industrial Internet Linkage: API integration with downstream industry MES systems enables end-to-end digital coordination of “orders-production-delivery,” building a “waste tire resource industrial internet platform.”

The emergence of automatic tire recycling systems represents not just a technological upgrade in waste tire processing, but a revolution in circular economy industrial models. Centered on “intelligence, unmanned operation, and digitization,” these systems solve the efficiency and quality pain points of traditional recycling. Meanwhile, their consistently high-quality recycled materials link infrastructure, rubber products, and new energy materials to form a positive “environmental disposal → resource reuse → economic value addition” cycle. Driven by global net-zero goals and circular economy policies, automatic tire recycling systems will become the mainstream solution for waste tire resource utilization—transforming “black pollution” into “green resources” while creating dual “environmental + economic” value for industry participants.