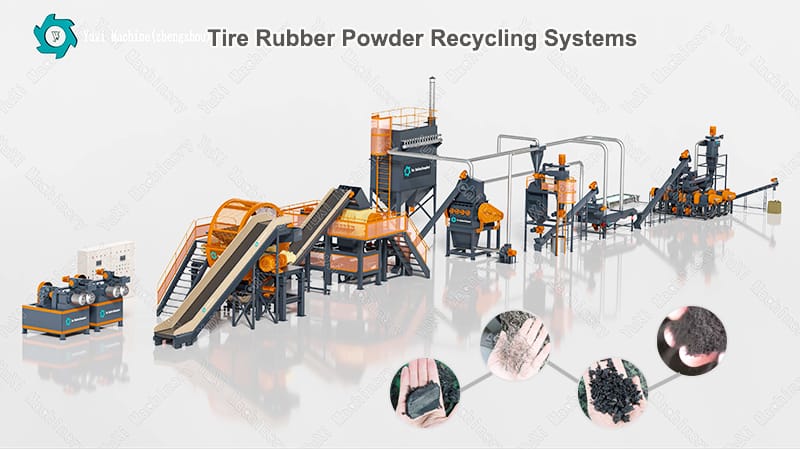

How Does Tire Rubber Powder Recycling System Enable High-Value Utilization of Waste Tires? Core Solution Breakdown

A deep dive into the full-process technology, core equipment selection, and high-value application scenarios of tire rubber powder recycling systems—unlocking the industrial path and dual environmental-economic benefits of waste tire resource utilization.

Global annual waste tire generation exceeds 1.5 billion units, with over 400 million scrapped annually in Europe and North America. These “black pollution” solid wastes are both ecological hazards and untapped “rubber resource banks.” As the core industrial solution for waste tire resource utilization, tire rubber powder recycling systems convert waste tires into high-purity recycled rubber powder through a closed-loop “physical shredding-multiphase separation-precision grinding” process. This powder is widely used in infrastructure, rubber products, high-end materials, and other fields, delivering triple value: environmental disposal, resource reuse, and economic returns. This article breaks down the industrial logic of this system across four dimensions: technical principles, equipment selection, application scenarios, and industry trends.

I. Technical Principles: Full-Process Breakdown from Waste Tires to Fine Rubber Powder

The core of tire rubber powder recycling systems is a “graded shredding-precise sorting-customized grinding” physical processing chain, which must simultaneously meet industrial requirements for “full resource recovery” and “high product purity.” The complete process consists of 5 core stages:

1.Pretreatment: Bead Separation & Primary Shredding (Loss Reduction Preprocessing)

Waste tires first enter a CNC tire bead cutter, where servo-driven blades precisely separate the high-strength steel beads (accounting for 15% of tire weight). This prevents hard metal from damaging subsequent equipment and allows the steel beads to be directly smelted and reused as tire frame materials.

Next, the tire body enters a hydraulically driven primary shredder, where it is cut into 5–10 cm rubber blocks. A 10 mm aperture circular screen sorts materials by particle size; undersized strips are recycled for secondary shredding to ensure material uniformity.

2.Multistage Shredding: Controllable Particle Size from Blocks to Granules

- Secondary intermediate shredders use a dual “shearing-compression” action to reduce 5–10 cm blocks to 6–12 mm coarse granules. Built-in variable-frequency speed control systems adapt to different tire hardness levels (e.g., heavy-duty truck tires, passenger car tires).

- Tertiary fine shredders use roll milling at room temperature to process coarse granules into 1–3 mm fine granules. The roll gap (0.5–2 mm) is precisely adjustable to match downstream powder size requirements (e.g., 3 mm powder for modified asphalt, <1 mm powder for high-end rubber products).

3.Multiphase Sorting: High-Purity Separation of Rubber/Steel/Fiber

This is the core stage for ensuring powder quality, using a combined “magnetic sorting-airflow sorting” process to separate multi-phase materials:

- High-gradient magnetic separators (≥1.4T magnetic field strength) separate capillary steel fibers (≤0.08 mm diameter) from granules, achieving a separation rate of over 99.5%.

- Eddy current airflow sorters use adjustable wind speeds (15–18 m/s) to separate rubber granules from nylon fibers (5% of tire weight); the fibers are reused as building material fillers.

4.Precision Grinding: Performance Assurance from Granules to Custom-Mesh Powder

Dual-disc intelligent grinding machines are the core equipment for powder refinement: multi-stage grinding rolls use coordinated shearing and rolling to process 1–3 mm granules into 40–200 mesh fine rubber powder. A roll temperature control system (≤55°C) prevents rubber aging due to high temperatures. 40–80 mesh powder is suitable for infrastructure scenarios (e.g., modified asphalt, rubber floor tiles); 120–200 mesh powder is used in high-end applications (e.g., recycled rubber products, coating modification).

5.Finished Product Post-Processing: Industrial Closed-Loop of Screening-Packaging-Dust Removal

Materials enter a vibratory graded screening system, where they are sorted into different specification finished products; undersized materials are recycled for regrinding. A quantitative vacuum bagging machine provides sealed packaging (to protect performance from moisture). A pulse baghouse dust removal system collects grinding dust, achieving an emission concentration ≤5 mg/m³ to meet industrial environmental standards.

II. Core Equipment Selection: Industrial Configuration Matching Capacity & Quality

Mature recycling system equipment selection must balance processing scale, product positioning, and operating costs. Below are technical parameters and application scenarios for 3 core equipment types:

- Rubber Shredding & Grinding Machine

Take the US CMI R600 model: with a processing capacity of 4–8 m³/h, it is suitable for medium-scale production lines (30–50 tons/day). It uses tungsten carbide alloy rolls (service life ≥6000 hours) and is paired with an intelligent operation and maintenance system to monitor equipment status in real time—balancing processing efficiency and equipment longevity. - High-Gradient Magnetic Separator

The German KHD 1250 model has a processing capacity of 10–20 t/h, with adjustable magnetic field strength and continuous operation (no blockages). It is suitable for high-end application scenarios requiring high-purity rubber powder (e.g., recycled rubber products). - Automated Control System

The Siemens S7-1500 PLC system enables full-process equipment linkage, real-time monitoring of temperature, current, and other parameters, and automatic shutdown protection in case of anomalies. It supports “single-operator” fully automated production lines, significantly reducing labor costs and operational risks.

III. High-Value Applications: Resource Utilization Paths from Infrastructure to High-End Materials

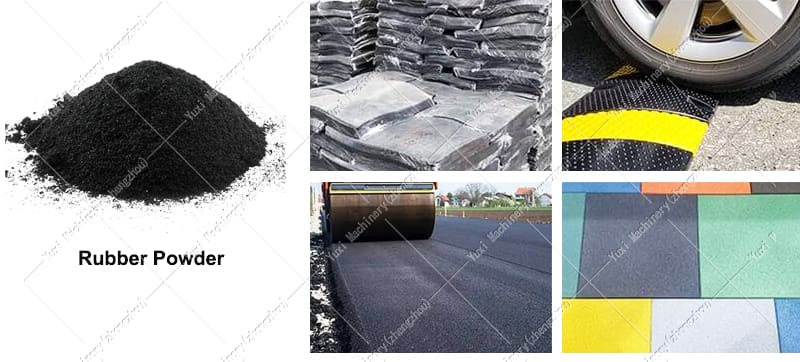

The economic value of recycling systems lies in expanding downstream application scenarios for rubber powder. Currently, mature high-value applications fall into 4 categories:

- Infrastructure: Performance Upgrade for Modified Asphalt

Modified asphalt mixed with 18–25% 40-mesh rubber powder improves pavement anti-aging performance by 45% and reduces driving noise by 12–18 dB; it is incorporated into EU road construction standards. Each ton of rubber powder replaces 25% of virgin asphalt, cutting raw material costs by 20–25%. - Recycled Rubber Products: Performance Reuse of Circular Materials

Fine rubber powder (≥120 mesh) blended with virgin rubber and adhesives can produce tire sidewalls, seals, brake pads, and other products—achieving over 90% of virgin rubber product performance while reducing raw material costs by 35–45%. It has been integrated into the supply chains of Michelin, Goodyear, and other enterprises. - High-End Materials: Value Leap from Carbon Black to Graphene

Through low-temperature pyrolysis, rubber powder can be converted into fuel (calorific value ≥45 MJ/kg) and high-purity carbon black (purity ≥92%). Further plasma modification extracts graphene (sheet thickness ≤3 nm) for use as a conductive agent in new energy batteries—boosting the economic value of each ton of waste tires from €2,200 to over €6,000. - Environmental Building Materials: Functional Enhancement for Waterproof Membranes

Adding rubber powder to asphalt waterproof membranes improves crack resistance by 25% and low-temperature resistance by 20°C, making it suitable for high-speed rail, subway, and other projects. European leading building material enterprises (e.g., Saint-Gobain) have implemented large-scale applications.

IV. Industry Trends: High-Value Circulation Driven by Policy

- Policy Dividends: Mandatory Advancement of Circular Economy

The EU Circular Economy Action Plan mandates a 90% waste tire recycling rate by 2030; the 2024 European and North American waste tire processing equipment market exceeded €1.2 billion, with complete recycling systems accounting for over 65% of the market. The US Tire Recycling Act also requires recycled rubber to make up at least 12% of tire content by 2028—ensuring significant industry growth driven by policy. - Technological Upgrades: From “Resource Utilization” to “High-Value Utilization”

The core industry upgrade direction is “high-value rubber powder utilization”: for example, biological desulfurization technology can improve recycled rubber performance to over 95% of virgin rubber; AI-driven grinding parameter optimization systems enable “customized rubber powder production” (e.g., precise adjustment of mesh size and elasticity based on downstream needs), further expanding high-end application scenarios. - Market Landscape: Industrial Barriers for Leading Enterprises

Fewer than 15 enterprises in Europe and North America offer complete system solutions. Leading players (e.g., US CMI, German KHD) have built full-chain service capabilities covering equipment supply, process output, and downstream channels. Their equipment achieves internationally leading levels of rubber powder purity (≥99.8%) and energy consumption (≤120 kWh/ton); industry concentration will continue to rise under dual policy and market drivers.