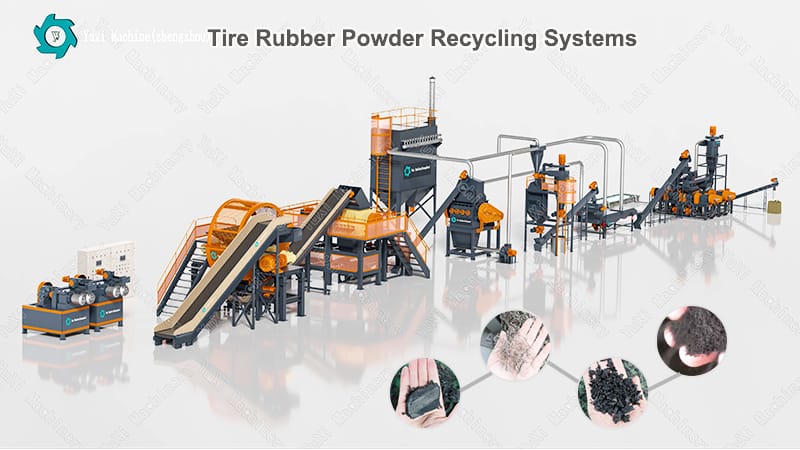

How to Build an Efficient Tire Rubber Powder Recycling System? A Full-Process Technical Solution Analysis

When an end-of-life tire reaches the end of its service life, it doesn’t have to become “black waste” that occupies land and causes pollution. A tire rubber powder recycling system can transform it into three types of resources—rubber powder, steel wire, and fiber—ultimately serving as a core raw material in modified asphalt, building materials, rubber products, and other fields. Today, we’ll break down the technical details, equipment logic, and industrial value of this system based on actual production line solutions.

Tire Rubber Powder Recycling System: Definition and Core Objectives

A tire rubber powder recycling system is an integrated production line combining “physical dissociation + sorting and purification.” Through processes like crushing, grinding, and separation, it converts end-of-life tires (a composite structure of rubber, steel wire, and fiber) into:

- Pure rubber powder with a particle size of 40–480 mesh;

- Steel wire raw material that can be directly recycled for smelting;

- Fiber impurities usable as filler.

Its core objective is to achieve “100% resource utilization” of end-of-life tires, while balancing three dimensions: volume reduction (over 90% volume compression), quality improvement (rubber powder performance adapted to downstream scenarios), and environmental protection (no secondary pollution).

Full Process of Tire Rubber Powder Recycling System: A Detailed Breakdown of 10 Core Steps

The actual production line process is not a simple stack of links, but a collaborative process of “gradual dissociation + cyclic sorting.” Taking a production line with a capacity of 11 tons per hour as an example, the complete process includes 10 core steps:

1.Automatic Wire Drawing Machine: Dismantle Tire Beads

The first step for end-of-life tires is to separate the “tire body” from the “bead.” The automatic wire drawing machine clamps the tire via a hydraulic device, uses a rotating cutter to cut the connection between the bead and the tire body, and disassembles the bead intact (it can be recycled separately later), while the tire body proceeds to the next step.

→ Purpose: Avoid bead wear on subsequent crushing equipment and improve the uniformity of tire body crushing.

2.Conveying Equipment: Full-Process Material Transfer

The production line is equipped with a combination of conveyor belts + screw conveyors + pneumatic conveying systems:

- Conveyor belts handle the transfer of large-volume materials (e.g., intact tire bodies, coarse rubber blocks);

- Screw conveyors enable sealed transfer of small-particle materials (e.g., rubber granules);

- Pneumatic conveying systems manage dust-free transfer of rubber powder.

→ Purpose: Enable continuous full-process operation, avoiding material accumulation or pollution.

3.Tire Crusher: Initial Crushing of Tire Body into Films

When the tire body enters the tire crusher, it is crushed into 2–6 inch rubber films via the engagement of “twin-shaft shear rollers.” The key here is “shearing rather than extrusion” to prevent rubber from sticking due to high temperatures, while initially loosening the bond between rubber and internal steel wire/fiber.

4.Steel Wire Separator: Preliminary Dissociation of Rubber and Steel Wire

After entering the steel wire separator, the rubber film is kneaded and torn by “high-speed rotating tooth rollers,” which preliminarily separates rubber and steel wire while crushing the rubber into 0.4–0.8 inch colloidal granules.

→ Output: Rubber-steel wire mixed granules (steel wire has been loosened from the rubber).

5.Magnetic Separator: Separate Steel Wire Impurities

When mixed granules pass through a high-intensity magnetic separator (magnetic field strength ≥ 15,800 gauss), steel wire is adsorbed to the collection bin due to magnetism, while rubber granules pass through the magnetic separation area. This step can separate over 98% of steel wire; fine steel wire will be further removed via “secondary magnetic separation” later.

6.Crusher: Refining Colloidal Granules

After magnetic separation, rubber granules enter the secondary crusher and are crushed into 0.04–0.3 inch small granules by “high-speed rotating impact cutter heads.” It is critical to control the cutter head speed (to prevent rubber aging from frictional heat) and use screens to ensure uniform particle size.

7.Vibrating Screen: Classification + Cyclic Crushing

Crushed granules enter the vibrating screen, which uses multi-layer screens of different meshes to divide granules into “qualified particle size (0.04–0.3 inch)” and “oversized granules”:

- Qualified granules proceed to the next step;

- Oversized granules are returned to the crusher via a recirculation device for secondary crushing.

→ Purpose: Ensure uniform particle size of rubber granules entering subsequent links and improve the quality stability of the final rubber powder.

8.Fiber Separator: Remove Fiber Impurities

When rubber granules enter the fiber separator, a combination of “airflow sorting + vibrating screening” is used:

- Lightweight fibers are blown to the collection bin by airflow;

- Rubber granules fall into the lower bin due to higher density.

→ Can remove over 95% of fiber impurities, ensuring rubber powder purity.

9.Secondary Magnetic Separation: Refined Steel Wire Removal

After fiber separation, rubber granules pass through the magnetic separator again. This step targets “fine steel wire debris” to further improve the purity of rubber granules (the final steel wire residue in rubber powder can be less than 0.1%).

10.Rubber Mill: Grinding Granules into Finished Powder

Pure rubber granules enter the rubber mill and are processed into 40–480 mesh rubber powder via the grinding action of “high-speed rotating grinding discs/needles” (particle size can be adjusted according to downstream needs).

→ Key Technology: The mill is equipped with a water cooling system to control the grinding temperature below 140°F, preventing rubber powder from cross-linking or aging due to high temperatures.

Core Equipment of the System: Functions and Advantages of 4 Key Machine Types

The efficiency and quality of the actual production line depend on the performance of core equipment. Taking a mainstream production line as an example, the functions of 4 key machine types are as follows:

- Twin-Shaft Tire Shredder

Function: Designed specifically for “classified shredding” of tire fragments. Fragments from the main shredder fall onto a rotating screen; smaller fragments enter the conveyor belt, while larger fragments are recirculated to the shredder for secondary crushing, resulting in uniform 2–2.4 inch fragments.

Advantage: Twin-shaft shear structure ensures high shredding efficiency and prevents material from wrapping around the rollers. - Tire Rasper

Function: Uses “tooth roller kneading + magnetic separation” to produce 99% steel-free rubber fragments (0.5–1 inch particle size). Steel wire can be packaged and sold to smelters, while rubber fragments can be directly colored for use as landscaping mulch.

Advantage: High dissociation efficiency, thorough steel wire separation, and “ready-to-use” rubber fragments. - Tire Rubber Granulator

Function: Uses physical methods to grind rubber granules into 0.04–0.24 inch fine granules; screening and cyclic processes ensure precise particle size compliance.

Advantage: Uniform granulation, no chemical additives, and preservation of the original properties of rubber granules. - Tire Rubber Powder Grinder

Function: Grinds 0.04–0.24 inch rubber granules into 40–480 mesh fine rubber powder; high-speed grinding discs enable continuous operation.Advantage: Easy operation, adjustable particle size, and compatibility with different types of end-of-life tires (passenger car tires, truck tires, engineering tires).

Core Features of the System: Advantages of Efficient, Intelligent, and Environmentally Friendly Production Lines

This tire rubber powder recycling system has become a mainstream industry solution due to 7 core features:

- Simplified Operation: Entire tires can be directly fed into the production line without pre-shredding or bead removal;

- Full-Process Continuity: From intact tires to 40–480 mesh rubber powder, there are no secondary processing links in production + packaging;

- High Capacity Adaptability: Maximum processing capacity of 11 tons per hour, with configurable capacity ranging from 0.55 to 11 tons per hour based on needs;

- Low Labor Cost: Only 7 personnel are required to operate the entire production line on-site;

- Easy Maintenance: Double-layer structure design makes equipment installation, replacement, and maintenance safer and more efficient;

- Environmentally Friendly and Dust-Free: Sealed conveying with seamless connections, combined with dust and fume monitoring systems, enables clean full-process production;

- Stable Performance: 80–100 hours of commissioning are required before delivery to ensure stable production line operation.

- Downstream Applications of Rubber Powder: High-Value Scenarios Across Multiple Fields

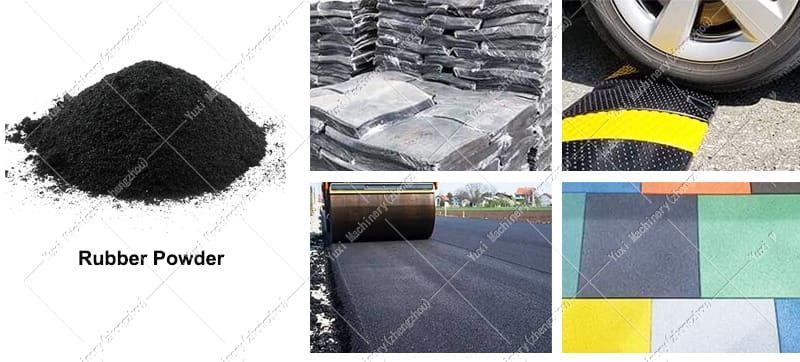

Rubber powder produced by the system is not low-quality filler, but a core raw material in multiple fields:

- Road Engineering: Used as an additive for modified asphalt (asphalt pavements with rubber powder have 30% better crack resistance and 25% better wear resistance);

- Building Materials: Used in the production of rubber floor tiles, roof coatings, and waterproof sealants (the elasticity of rubber powder improves the shock absorption and sound insulation performance of building materials);

- Rubber Products: Fine-mesh rubber powder can replace 20–30% of virgin rubber in the production of seals, conveyor belts, etc.;

- Other Scenarios: Used as filler for thermoplastic materials and reinforcing agent for geomembranes.

Conclusion: Industrial Value of Tire Rubber Powder Recycling Systems

The significance of this system goes far beyond the environmental goal of “processing end-of-life tires”:

- For the Environment: It can handle tens of millions of end-of-life tires annually, solving the problem of “black pollution”;

- For Industry: It provides low-cost, high-performance raw materials for road, building materials, rubber, and other industries, driving circular upgrading of the industrial chain;

- For the Economy: It realizes a value cycle of “end-of-life tires → resources → products,” creating new industrial growth points.

From “black waste” to “circular resources,” the tire rubber powder recycling system is a typical case of coordinated development of “environmental protection + industry + economy.” With further technological upgrades, it will evolve toward “intelligence (AI-controlled particle size and energy consumption)” and “high value (nano rubber powder, functional rubber powder)” in the future, unlocking even greater value.