How to Configure a Tire Rubber Granule Recycling System to Balance Quality and Profit?

Disassemble the core composition, key selection points, and profit paths of the tire rubber granule recycling system, helping enterprises improve granule quality, reduce costs, and achieve a per-ton profit increase of more than 40%.

I. What Is a Tire Rubber Granule Recycling System? Why Is It a Necessity for Processing?

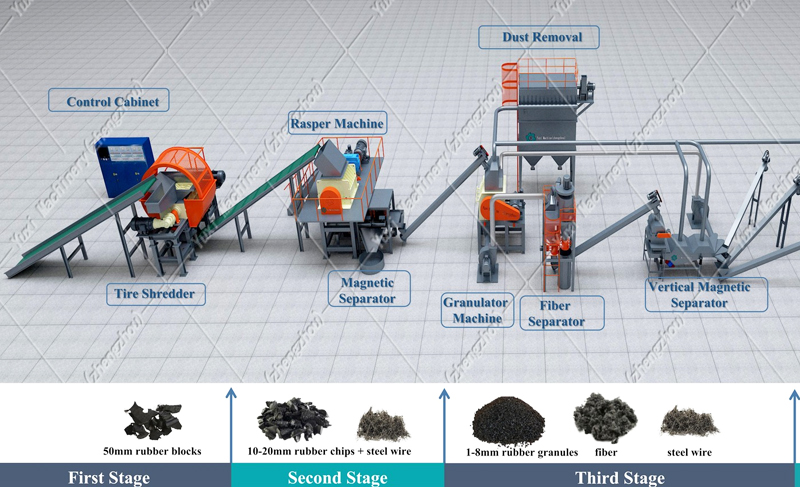

Rubber granules are the core profitable product in waste tire resource utilization, widely used in sports fields, rubber products, modified asphalt and other fields. The tire rubber granule recycling system is a complete production line that realizes the transformation from “waste tires to standardized granules”. Through the full-process collaboration of “preprocessing – crushing – classification – separation – packaging”, it produces granules of 1-50mm specifications, with a steel wire and fiber separation rate of ≥99% and product purity of more than 99%, completely solving the pain points of traditional processing such as “uneven granules, high impurities, and unstable production capacity”.

Data comparison: Traditional processing has a per-ton cost of $14.5, qualification rate of 70%, and selling price of $116/ton; the complete set of system has a per-ton cost of ≤$8, qualification rate of 95%, and high-quality granules selling price of $174-$261/ton, doubling the per-ton profit and increasing annual net profit by more than 40%.

II. Core Composition and Functions of the System

- Raw Material Preprocessing Unit

- Equipped with automatic feeding machine, bead cutting machine, sorter, and block cutting machine, it removes impurities and cuts whole tires into 5-10cm blocks, improving subsequent efficiency by 25% and reducing blade wear by 30%.

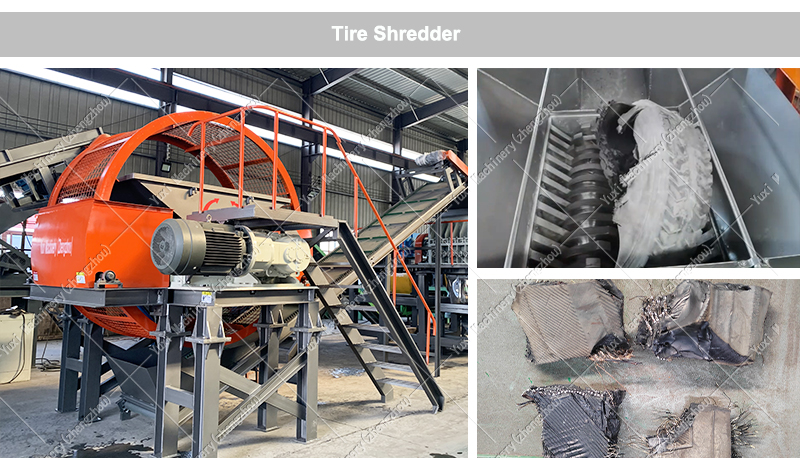

- Graded Crushing Unit

Adopting a three-stage mode of “coarse crushing + medium crushing + fine crushing”, the shear-type coarse crusher, hammer-type medium crusher, and roller-type fine crusher work together. The rotation speed (300-600rpm) and blade gap are adjusted according to granule specifications to ensure uniform granules. - Classification and Separation Unit

Different specifications of granules are sorted through a vibrating classification screen, steel wires are separated by a high-strength magnetic separator (magnetic field ≥12000Gs), and fibers are removed by an air classifier, which improves product added value. The selling price is $29-$43.5 higher per ton than unclassified products. - Environmental Protection Processing Unit

Equipped with a pulse bag filter (dust emission ≤1mg/m³) and sound insulation cover (noise ≤85 decibels). For European and American markets, an additional VOCs treatment device is required to meet EPA and OSHA standards, avoiding monthly fines of $1,450-$4,350. - Storage and Packaging Unit

Including finished product silo, automatic quantitative packaging machine, and AGV robot, it realizes standard packaging of 25kg/50kg with an error of ≤±0.5kg, reducing manual loss and improving shipment efficiency.

III. Core Selection Points of the System

Choose Configuration According to Granule Specifications

- Fine granules (1-5mm): Three-stage crushing + purification and modification, daily production capacity 8-15 tons, investment $217,500-$362,500;

- Medium granules (5-20mm): Two-stage crushing + classification and separation, daily production capacity 15-25 tons, investment $145,000-$261,000;

- Coarse granules (20-50mm): One-stage crushing + simple classification, daily production capacity 20-30 tons, investment $87,000-$174,000.

Choose Equipment According to Raw Material Type

- Passenger car tires: Hammer-type crushing + simple magnetic separation, reducing investment by 10-15%;

- Commercial vehicle steel-belted tires: Shear-type coarse crushing + high-strength magnetic separation to ensure thorough steel wire separation;

- Mixed raw materials: Heavy-duty block cutting machine + multi-stage composite crushing, adapting to tires of different hardness.

Choose Supporting Facilities According to Environmental Standards

- Domestic: Dust collector + sound insulation system, dust ≤2mg/m³, noise ≤85 decibels;

- European and American: Must pass EPA and OSHA certifications, equipped with environmental monitoring system and ISO14001 certification.

Choose Material and Design According to Cost

Core components are made of high-chromium alloy (hardness ≥HRC60) with a service life of 800-1200 tons; choose frequency conversion equipment + waste heat recovery to reduce energy consumption by 15-20%.

IV. Simplified Guide for Use and Operation and Maintenance

- Installation and Debugging

Cement ground foundation ≥30cm, stable voltage (fluctuation ≤±3%), carry out load operation after 24-hour no-load trial operation without abnormalities. - Daily Operation

After setting parameters, feed materials at a uniform speed, check granule size every hour, and regularly clean the screen and fiber collection box to ensure separation effect. - Maintenance Points

Daily: Check lubricating oil and clean filter bags;

Weekly: Tighten bolts and calibrate packaging accuracy;

Monthly: Replace lubricating oil and overhaul environmental protection equipment.

V. Frequently Asked Questions

Q1: What is the investment payback period?

A: 8-10 months for small-scale coarse granule lines, 12-15 months for medium-scale medium granule lines, 15-18 months for large-scale fine granule lines; it can be shortened by 20-30% when docking with high-end customers.

Q2: How to increase the selling price of granules?

A: Ensure purity (≥99%) and uniformity, carry out purification and modification, obtain environmental certifications, and expand European and American markets (selling price 30-50% higher).

Q3: How to reduce processing costs?

A: Choose energy-saving equipment, optimize processes, and do a good job in maintenance; per-ton cost can be reduced by 10-15%.

The tire rubber granule recycling system is a comprehensive solution integrating “process + equipment + compliance + operation”. Selection should focus on the core of “granule specifications, raw materials, environmental protection, and cost”. Good operation and maintenance can stably produce high-value granules, which become the core of enterprise profits. A high-quality system is the key tool to tap the high-profit market of waste rubber.