How to Configure a Tire Rubber Powder Recycling System? Compliance and Efficient Operation Guide Here

Comprehensively analyze the core composition, selection key points, environmental compliance solutions, and profit logic of tire rubber powder recycling systems, helping waste rubber processing enterprises improve production capacity, optimize quality, and achieve an annual revenue growth of over 30%.

I. What Is a Tire Rubber Powder Recycling System? Why Is It the Core Choice for Waste Rubber Processing?

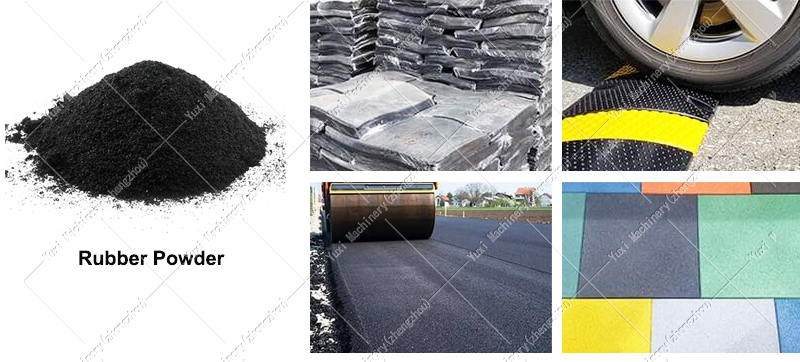

In the waste tire resource utilization industry chain, “rubber powder” is a high-value-added core product with stable market demand. The tire rubber powder recycling system is a complete production line integrating preprocessing, crushing, grinding, separation, dust removal, and storage. It can process waste tires into 10-120 mesh fine rubber powder, realize complete separation of steel wires and fibers, and operate fully automatically.

Compared with traditional decentralized processing, the complete set of recycling system reduces the loss rate from 15% to less than 5%, and the processing cost per ton drops from over $17.5 to within $8.7. Enterprises equipped with this system can increase rubber powder selling price by $29-$43.5 per ton, with annual profits growing by more than 30%.

II. Core Composition and Functions of Tire Rubber Powder Recycling System

- Preprocessing Unit

Equipped with tire cutting machine, bead wire separator, and foreign matter sorter, it removes impurities and splits tires into 5-10cm blocks, improving subsequent processing efficiency by 20% and reducing blade wear by 30%. - Crushing Unit

Adopts two-stage crushing (coarse + medium): coarse crusher processes tire blocks into 20-50mm particles, medium crusher into 5-10mm particles, and realizes initial steel wire separation (over 80%) via built-in magnetic separator. - Grinding Unit

Core hub of the system, with primary and secondary grinding. Roller grinders are suitable for 40-80 mesh medium powder, impact grinders for 80-120 mesh fine powder, ensuring uniform particle size and high purity. - Separation and Purification Unit

Uses air classifier and electrostatic separator to remove residual fibers and impurities, increasing rubber powder purity to over 99% and raising product selling price by $21.7-$29 per ton. - Environmental Protection Unit

Equipped with pulse bag filter (filtering area ≥200㎡, dust emission ≤1mg/m³), sound insulation cover (noise ≤80 decibels), and VOCs treatment device, meeting European and American environmental standards and avoiding fines of $1,450-$4,350 per month. - Storage and Conveying Unit

Includes screw conveyor, bucket elevator, finished product silo, and quantitative packaging machine, ensuring continuous production and reducing manual intervention.

III. Key Selection Dimensions for Tire Rubber Powder Recycling System

By Target Product Particle Size

- Coarse powder (10-40 mesh): Suitable for roadbed filling; configuration: preprocessing + primary crushing/grinding; daily capacity 15-25 tons, investment $116,000-$174,000.

- Medium powder (40-80 mesh): Suitable for rubber product recycling; configuration: two-stage crushing/grinding + complete separation; daily capacity 20-30 tons, investment $217,500-$290,000.

- Fine powder (80-120 mesh): Suitable for high-end modified asphalt; configuration: three-stage grinding + deep purification; daily capacity 15-25 tons, investment $362,500-$507,500.

By Raw Material Type

- Passenger car tires: Choose hammer crushing + impact grinding, low energy consumption.

- Commercial steel-belted tires: Choose shear crushing + roller grinding, with high-strength magnetic separator (steel wire separation rate ≥99%).

- Mixed raw materials: Equip heavy-duty pre-cutting machine + multi-stage composite grinding.

By Environmental Standards

For European and American markets: Meet EPA (dust ≤0.5mg/m³) and OSHA (noise ≤85 decibels) standards, with environmental parameter monitoring and traceability functions.

By Operation Cost

Choose high-chromium alloy blades (service life 800-1200 tons) and frequency conversion energy-saving equipment, reducing energy consumption by 15-20%.

IV. Basic Use and Maintenance Guidelines

- Installation and Debugging

Choose cement ground (foundation thickness ≥30cm), ensure stable voltage (fluctuation ≤±3%), and run no-load for 24 hours before load operation. - Standard Operation

Follow the sequence of “environmental protection → conveying → grinding → crushing → preprocessing” for startup; check particle size hourly, ensure magnetic field strength ≥12000Gs, and control finished product humidity ≤8%. - Daily Maintenance

Clean filter bags and dust collection boxes daily; check lubricating oil and blade wear weekly; replace oil and overhaul environmental protection equipment monthly.

V. Common Questions and Answers

Q1: What is the investment payback period?

A: 1.5-2 years for small lines, 1-1.2 years for medium lines, and 1.5 years for large lines; can be shortened by 30% with high-end customers or government subsidies.

Q2: How to enter European and American markets?

A: Meet product purity (≥99%), pass EPA/OSHA standards, and obtain ISO9001, ISO14001, and REACH certifications.

Q3: How to reduce energy consumption?

A: Choose frequency conversion equipment, optimize processes, and utilize waste heat recovery, reducing electricity consumption per ton from 80kWh to below 60kWh.

The tire rubber powder recycling system is a comprehensive solution integrating process, equipment, and compliance. By selecting configuration based on target products and raw materials, and focusing on environmental protection and energy saving, enterprises can improve product value, connect with high-end markets, and realize profit doubling. For European and American market expansion, strict compliance and product certification are the core keys.