How to Implement an Automatic Tire Recycling System? Efficient and Intelligent Operation Guide Here

In-depth analysis of the core architecture, selection logic, intelligent upgrading solutions, and profit paths of automatic tire recycling systems, helping recycling enterprises realize full-process automated production, reduce labor costs by more than 40%, and increase annual production capacity by 50%.

I. What Is an Automatic Tire Recycling System? Why Has It Become a Standard Upgrade for the Recycling Industry?

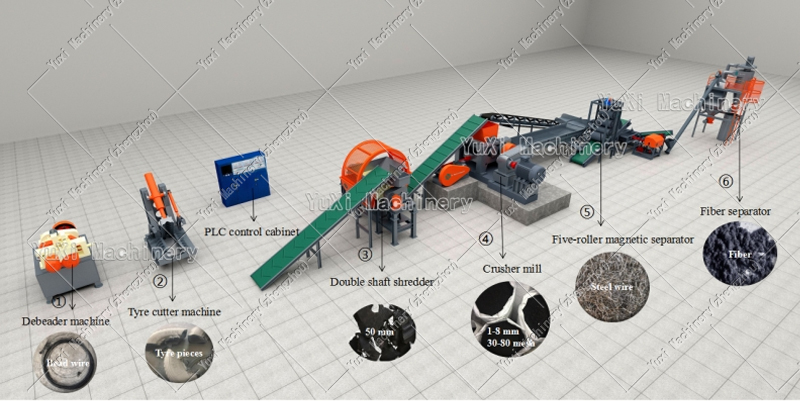

With the large-scale development of the waste tire recycling industry, “automation” is the core direction to break through production capacity bottlenecks and reduce operating costs. An automatic tire recycling system is an integrated full-process automated production line that combines “raw material conveying, crushing and decomposition, material separation, finished product storage, and intelligent monitoring”. It can realize graded resource processing of waste tires from “whole tires” to “rubber granules, steel wires, and fibers” without manual intervention in key processing links. Only 2-3 personnel are needed to monitor equipment and supplement raw materials, with a daily production capacity of 10-50 tons, completely solving the pain points of traditional recycling models such as “labor-intensive, low efficiency, and high loss”.

For traditional manual-assisted recycling lines, the labor cost per ton of processing is about $11.6, and the production capacity fluctuation reaches 20%; while the labor cost per ton of an automatic tire recycling system can be reduced to less than $6.5, the production capacity stability is increased to more than 95%, and the product purity is higher, significantly enhancing the bargaining power in docking with downstream markets. It is suitable for medium and large recycling enterprises and entrepreneurs who want to expand large-scale businesses.

II. Core Architecture and Intelligent Advantages of Automatic Tire Recycling Systems

A mature automatic tire recycling system focuses on “equipment collaboration + intelligent control”. Each unit is linked through a PLC control system to realize full-process closed-loop operation. The specific architecture and advantages are as follows:

- Intelligent Feeding and Preprocessing Unit: Precisely Control Raw Material Rhythm

Core equipment includes automatic feeding machines, intelligent sorters, and automatic bead cutting machines. It identifies tire size and impurities through sensors, automatically adjusts feeding speed to avoid equipment overload; at the same time, it automatically peels off tire bead wires and removes foreign objects such as stones, with a preprocessing qualification rate of over 98%. Compared with manual preprocessing, the efficiency is increased by 3 times, and the impurity residue rate is reduced to less than 1%. - Automatic Crushing and Decomposition Unit: Graded Processing, Stable and Efficient

Adopting a three-stage automatic crushing mode of “coarse crushing + medium crushing + fine crushing”, the crushing parameters are set through the PLC system. According to the tire type (passenger car tires, commercial vehicle tires), the rotor speed (300-800rpm) and blade gap are automatically adjusted to gradually process whole tires into 5-20mm rubber granules without over-crushing or uncrushed phenomena, and the particle uniformity is increased by 40%. - Intelligent Separation and Purification Unit: More Thorough Material Sorting

Integrating automatic magnetic separators, air classifiers, and electrostatic separators, it identifies the physical properties of different materials through intelligent sensors, automatically adjusts magnetic field strength and air flow speed, and realizes precise separation of steel wires, fibers, and rubber granules — the steel wire separation rate is ≥99%, the fiber removal rate is ≥95%, and it can automatically collect sorted materials to avoid secondary mixing and improve the added value of finished products. - Automatic Storage and Packaging Unit: More Efficient Finished Product Management

Equipped with intelligent finished product silos, automatic quantitative packaging machines, and AGV transfer robots. After passing the inspection, finished granules are automatically stored in corresponding positions. According to order requirements, standard packaging of 25kg/50kg is realized with a packaging error of ≤±0.5kg. Then AGV robots automatically transfer them to the storage area, without manual handling throughout the process. The storage efficiency is increased by 50%, and finished product loss is reduced. - Intelligent Monitoring and Operation and Maintenance Unit: Ensure Stable System Operation

Equipped with an Industrial Internet of Things (IoT) module, it can real-time monitor equipment operation status (speed, temperature, production capacity), energy consumption data, and product quality parameters through a touch screen or remote terminal. When an abnormality occurs, it automatically alarms and pushes the cause of the fault. It also has an equipment maintenance reminder function, which shortens the shutdown maintenance time by 30% and extends the equipment service life to 8-12 years.

III. Key Selection Points for Automatic Tire Recycling Systems: 4 Dimensions to Adapt to Needs

Choose System Specifications According to Production Capacity Scale

- Small-scale automatic system: Daily production capacity 10-20 tons, floor area 300-500㎡, suitable for start-up large-scale enterprises, investment cost $116,000-$217,500, only 2 personnel needed for monitoring and operation;

- Medium-scale automatic system: Daily production capacity 20-30 tons, floor area 600-1000㎡, suitable for regional recycling enterprises, investment cost $217,500-$435,000, equipped with intelligent monitoring system, supporting remote operation and maintenance;

- Large-scale automatic system: Daily production capacity 30-50 tons, floor area 1000-1500㎡, suitable for national leading recycling enterprises, investment cost $435,000-$870,000, equipped with full-process intelligent scheduling system, which can be connected to ERP management platform.

Choose Core Configuration According to Raw Material Type

- Mainly passenger car tires: The raw materials are relatively soft, the combination of “hammer-type crushing + impact-type separation” can be selected, and a light automatic feeding system is configured to reduce energy consumption;

- Mainly commercial vehicle steel-belted tires: The raw materials have high hardness and high steel wire content, so the combination of “shear-type crushing + high-strength magnetic separation” must be selected, and a heavy-duty automatic bead cutting machine is equipped to improve crushing efficiency and separation effect;

- Mixed raw materials (including engineering tires and solid tires): It is necessary to configure a “heavy-duty automatic pre-cutting machine + multi-stage composite crushing” system, equipped with raw material identification sensors to automatically switch processing parameters.

Choose Upgrade Modules According to Intelligent Needs

- Basic intelligent version: Equipped with automatic start-stop, parameter monitoring, and abnormal alarm functions, meeting basic automated production needs;

- Advanced intelligent version: Added remote operation and maintenance, energy consumption statistics, and automatic production report generation functions, adapting to refined management needs;

- High-end intelligent version: Equipped with AI visual inspection, intelligent scheduling, and upstream and downstream supply chain docking functions, realizing full-link digital operation.

Choose Supporting Facilities According to Environmental Standards

- Domestic compliance needs: Configure pulse bag filter (dust emission ≤2mg/m³) and sound insulation system (noise ≤85 decibels) to meet industrial environmental protection requirements;

- European and American market needs: Must meet EPA dust emission standards (≤0.5mg/m³) and OSHA noise standards (≤80 decibels), configure VOCs treatment device and environmental protection parameter traceability system, and obtain ISO14001 certification.

IV. Key Points for the Use and Operation and Maintenance of Automatic Tire Recycling Systems

Installation and Debugging

Choose a cement-poured ground (foundation thickness ≥30cm) to ensure the ground flatness error ≤5mm; connect to a stable industrial power supply, configure an independent transformer and overload protection device; after completing equipment installation, conduct no-load trial operation for 48 hours, debug the collaboration accuracy of each unit, and carry out load operation only after ensuring parameters meet standards.

Daily Operation

Set production parameters (production capacity, particle size) through the intelligent terminal. After starting the system, only need to monitor raw material supply and equipment operation status; regularly check intelligent reports, analyze production capacity, energy consumption, and product quality data, and optimize processing parameters; strictly screen raw materials according to system reminders to avoid large foreign objects entering the equipment.

Maintenance

- Daily: Check equipment temperature and lubricating oil level through intelligent monitoring, and clean dust collector filter bags;

- Weekly: Check the tightness of transmission components and calibrate the accuracy of quantitative packaging;

- Monthly: Replace equipment lubricating oil and detect the sensitivity of sensors and intelligent modules;

- Annually: Conduct comprehensive disassembly and maintenance, replace severely worn core components, and upgrade intelligent system firmware.

V. Frequently Asked Questions

Q1: What is the investment payback period of an automatic tire recycling system?

A: About 1.5-2 years for small-scale systems, 1-1.5 years for medium-scale systems, and 1.2-1.8 years for large-scale systems; if docking with high-end downstream markets or enjoying government recycling subsidies, the payback period can be shortened by 20-30%.

Q2: Compared with traditional production lines, how much cost can an automatic system save?

A: Labor costs are reduced by 40-60% (calculated by daily production capacity of 20 tons, saving 200,000-300,000 yuan in labor costs annually), raw material loss is reduced by 10-15%, energy consumption is reduced by 15-20%, and comprehensive operating costs are reduced by more than 30%.

Q3: If the system malfunctions, can non-professionals handle it?

A: Basic faults (such as raw material jamming and parameter abnormalities) can be manually handled according to the fault solution pushed by the system; complex faults (such as core component damage and intelligent module faults) need to contact the manufacturer for remote guidance or on-site maintenance. High-end systems have fault self-diagnosis and partial self-healing functions.

VI. Summary: Automation Upgrade, Unlocking New Momentum for the Tire Recycling Industry

An automatic tire recycling system is not a simple integration of equipment, but a core grasp for recycling enterprises to realize “cost reduction, efficiency improvement, and quality enhancement” — through full-process automated production, it gets rid of labor dependence and stabilizes production capacity and product quality; through intelligent upgrading, it realizes refined management and improves market competitiveness; through compliant configuration, it docks with high-end markets and expands profit space.

When selecting, closely focus on the four cores of “production capacity, raw materials, intelligent needs, and environmental standards”, and do a good job in daily operation and maintenance. A high-quality automatic tire recycling system can become the “core engine” for the large-scale development of enterprises, helping to seize opportunities in the waste tire resource utilization track.