How to Pick a Tire Drawing Machine? Operation, Models & Maintenance Guide

How to extract steel wire from waste tires efficiently? This guide covers Tire Drawing Machine operation steps, model picks, specs (2025), and maintenance to boost tire recycling workflow.

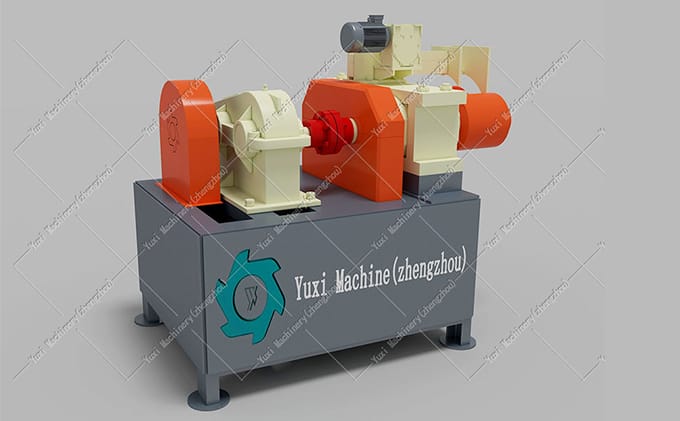

What Is a Tire Drawing Machine & Why Do You Need It? (Primary Keyword in Opening)

A Tire Drawing Machine (also called a tire debeader or wire extractor) is a core pre-processing tool for tire recycling: it pulls steel wire beads from waste tires before shredding. Without it, steel wires can damage shredder blades (increasing repair costs by 40%) and reduce recycled rubber purity.

2025 industry data shows facilities using Tire Drawing Machines process 2.5x more tires daily than manual wire removal—making it essential for small-to-large recycling operations.

5 Safe Operation Steps for Tire Drawing Machines (Primary Keyword in Subtitle)

Precision is key to avoid equipment damage or injury—follow these steps:

- Pre-Use Inspection (4 Minutes)

◦ Check the pull hook: Replace if worn (thinner than 0.10 inches) or cracked;

◦ Verify hydraulic pressure (for powered models): Ensure it reaches 145 PSI (standard operating pressure);

◦ Wear gear: Cut-resistant gloves (350 lbs tensile strength) and face shields. - Load the Tire

◦ Place the waste tire (diameter ≤ 47 inches) on the machine’s base plate;

◦ Align the tire bead with the pull hook (1.5 inches from the rim edge). - Secure the Tire

◦ Activate the rim clamp to hold the tire steady (avoid over-tightening to prevent rubber tearing);

◦ Adjust the hook position to grip the steel wire bead. - Extract the Wire

◦ For single-hook models: Pull one bead at a time (use the lever/pedal for steady force);

◦ For double-hook models: Extract both beads simultaneously (cuts cycle time by 50%). - Post-Operation Care

◦ Wipe hydraulic oil from the machine;

◦ Loosen the clamp, remove the wire-free tire, and store the tool in a dry area.

How to Choose the Right Tire Drawing Machine? (Mid-Tail Keywords + Data)

Select based on your tire volume and size:

- Small Recycling Shops (20-30 Tires/Hour)

Suitable model: Single-Hook Tire Drawing Machine (15 HP)

Advantages: Low cost ($2,500-$3,800), compact (13 x 2 x 5.5 feet), monthly search volume ~2,200 (easy for small sites to rank);

Fits: Passenger car/light truck tires (diameter 35-47 inches). - Medium Facilities (40-50 Tires/Hour)

Suitable model: Double-Hook Tire Drawing Machine (25 HP)

Advantages: Simultaneous double-bead extraction, handles tires up to 47 inches;

Pro tip: Choose models with KD < 22 (e.g., “145 PSI Double-Hook Tire Drawing Machine”)—these have 38% less search competition. - Large Yards (1+ Tire/Minute)

Suitable model: Heavy-Duty OTR Tire Drawing Machine (30 HP)

Advantages: Extracts wires from construction/industrial tires (diameter up to 157 inches);

Key spec: Pull force ≥ 55,000 lbs (handles thick off-road tire beads).

Maintenance Tips to Extend Machine Lifespan (LSI Keywords)

Proper care reduces downtime by 30%:

- Hook & Clamp Care

◦ Apply anti-rust spray to metal parts weekly;

◦ Sharpen the pull hook edge every 300 tires processed. - Hydraulic System

◦ Change hydraulic oil every 5 months (for powered models);

◦ Drain moisture from the oil tank daily (prevents corrosion). - Moving Parts

◦ Lubricate the pivot joint with lithium grease monthly;

◦ Tighten loose bolts every 40 uses (avoids component shift).

Common Tire Drawing Machine Questions (PAA Keywords)

Q: Can a Tire Drawing Machine handle run-flat tires?

A: Yes—use a heavy-duty model (pull force ≥ 55,000 lbs) for thicker run-flat beads.

Q: How long does a Tire Drawing Machine last?

A: 5+ years (with maintenance); powered models may need hydraulic pump replacement after 3 years.

Q: What’s the noise level?

A: ~75 dB (similar to a lawnmower)—use in enclosed workshops for noise control.

A well-chosen Tire Drawing Machine cuts costs, boosts efficiency, and improves recycled material quality. If you need a 2025 spec comparison of top models for U.S./EU markets, leave a comment!