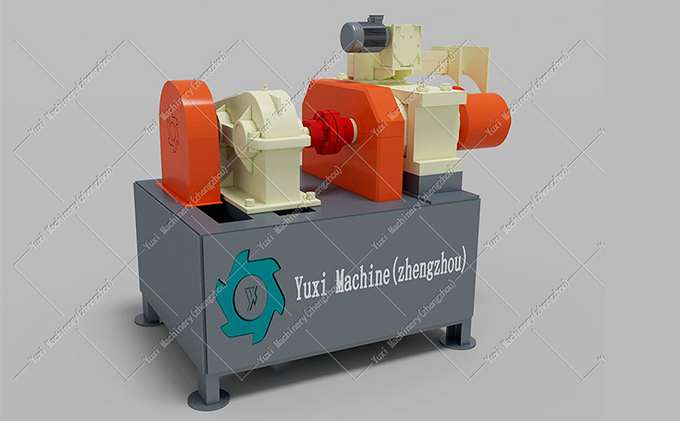

Hydraulic or Pneumatic Tire Drawing Machine? The Answer Is Here

Learn about the key points for selecting, using, and maintaining tire drawing machines to help auto repair shops improve tire removal efficiency, reduce wheel hub wear and tear, and save 30% of costs by choosing the right equipment.

I. What Is a Tire Drawing Machine? Why Do Auto Repair Shops Need It?

If you’re an auto repair shop owner, you must have encountered “stuck tires that can’t be removed” — 3 workers prying for 10 minutes, scratching the wheel hub, tearing the tire, and wasting time. A tire drawing machine is the “tire removal tool” that solves this problem: it can separate the tire from the wheel hub without damage in 3 minutes using hydraulic/pneumatic power, and can be operated by 1 person, saving 2-3 hours of working time every day.

Using a tire drawing machine for tire removal reduces wheel hub wear rate from 15% to 1%, and the annual cost saved is enough to cover the price of an entry-level machine.

II. 5 Core Functions of Tire Drawing Machines (Solving Your Actual Pain Points)

- Quick Tire Removal in 3 Minutes, 3x Efficiency Improvement

Traditional manual tire removal requires 2-3 workers and takes 10-15 minutes; a tire drawing machine only needs 1 person and takes 3-5 minutes to complete — for shops that remove 30 tires per day, this means 5 more orders can be handled daily.

Suitable Scenarios: “Stuck tires” that haven’t been removed for a long time, tires that harden in low temperatures, and batch tire replacement for fleets. - Protect Wheel Hubs from Scratches, Save +$5000 Annually

When removing tires manually with a crowbar, 3 out of 10 aluminum alloy wheel hubs will be scratched; the rubber-wrapped claws of a tire drawing machine can 100% avoid damage to the hub’s paint or electroplated layer.

Cost Comparison: For a $500 wheel hub, the annual replacement cost due to scratches is enough to buy an entry-level tire drawing machine. - Compatible with 13-28 Inch Wheel Hubs, Covering 90% of Shop Needs

A high-quality tire drawing machine can not only handle passenger car tubeless tires but also be compatible with commercial vehicle steel-belted tires, engineering vehicle giant tires, and even motorcycle tires — one device can replace 3 types of manual tools.

Usage Tip: When removing large commercial vehicle tires, matching an “auxiliary support arm” makes it more stable. - Reduce Labor Intensity, Avoid Lumbar Muscle Strain

Manual tire removal requires bending and exerting force, which can easily cause lumbar muscle strain with long-term operation; a tire drawing machine is controlled by a foot switch, and workers only need 3 steps: “fix — place claws — start”, reducing labor intensity by 70%. - Support Tire Retreading, Expand Profit Margins

The “low-tension mode” of the machine can separate old tires completely without damaging the tire body cords — allowing shops to expand from “tire replacement” to “tire retreading + repair”, doubling the profit per tire.

III. How to Choose a Tire Drawing Machine? 3 Dimensions to Avoid Pitfalls

Choose the Drive Method Based on Business (Don’t Waste Money)

- Hydraulic Drive: Pull force 8-18 tons, motor power 2.2-3.7kW, suitable for commercial vehicle/run-flat tires, stable and durable, but weighs 120-250kg and requires fixed installation;

- Pneumatic Drive: Working pressure 90-120PSI, pull force 5-9 tons, suitable for passenger car tires, low noise and relatively flexible, can be used by connecting to an air compressor;

- Electric Drive: Built-in 1.5-2.5kW motor + hydraulic pump, no need for an air compressor, suitable for mobile tire repair, slightly higher price.

Choose the Compatibility Range Based on Size (Avoid Buying One That’s Too Small)

- Passenger Car Special: 13-22 inch wheel hubs, pull force 5-9 tons, suitable for shops that remove 20 tires or fewer per day;

- Commercial Vehicle Compatible: 17-28 inch wheel hubs, pull force 10-18 tons, suitable for shops with commercial vehicle business;

- Full-Scenario Universal: 13-30 inch wheel hubs, pull force 8-18 tons, suitable for auto repair chains/retreading plants.

Check Additional Configurations (Improve Experience)

- For low-temperature areas, choose the “tire bead heating” function, heating temperature up to 140-160°F (60-70°C), making tire removal easier in low temperatures;

- For large tires, choose the “auxiliary support arm”, load capacity up to 200-300lbs (90-136kg), avoiding tire shaking;

- To protect wheel hubs, choose “flexible claws”, wrapped in Durometer 70-80 Shore A rubber, no scratches.

IV. 4-Step Tutorial for Using and Maintaining a Tire Drawing Machine

- Installation and Debugging

- Place on a flat surface to ensure levelness and avoid tilting;

- Check the hydraulic oil level, use ISO VG 32-46 hydraulic oil, and start only if there is no leakage;

- Replace claws according to wheel hub size and adjust the stroke.

- Operation Steps

- Fix the wheel hub: Place it on the turntable and clamp it with the chuck to ensure no shaking;

- Install the claws: Align with the “separation point” of the tire bead and ensure full fit;

- Start the machine: Step on the foot switch, apply force slowly, and observe the separation situation;

- Remove the tire: Stop the machine after the tire bead is completely separated, and take out the tire.

- Daily Maintenance

- Clean the claws and hydraulic system every day to wipe off oil stains;

- Replace anti-wear hydraulic oil every 250-300 hours to avoid rusting of the oil cylinder;

- Regularly check the rubber layer of the claws, and replace it promptly if the wear exceeds 1/8 inch (3mm).

V. Common Questions About Tire Drawing Machines (All Your Concerns Answered)

Q1: Can carbon fiber wheel hubs use a tire drawing machine?

A: Yes, but you need to choose a model with “soft claws” to avoid scratching the surface; for modified wide-edge wheel hubs, adjust the claw stroke.

Q2: Do I need to deflate the tire before removal?

A: Yes, completely — air pressure in the tire will make the bead fit tighter, increasing removal difficulty and possibly causing the tire to burst.

Q3: Is bigger pull force better?

A: No — choose 5-9 tons for passenger cars and 10-18 tons for commercial vehicles; too much pull force can easily deform the wheel hub.

VI. Summary: Choose the Right Tire Drawing Machine, Save Worry, Effort, and Cost

A tire drawing machine is not an “expensive device” but a “money-making tool” that helps you improve efficiency, reduce wear and tear, and expand business. Choose based on “drive method + compatibility size + additional configurations” and maintain it properly, and one machine can be used for 5-8 years, helping you earn $2,000-$3,000 more per year.