Automatic Tyre Recycling Systems

What is Automatic Extrusion Type Tyre Recycling System

The Automatic Extrusion Type Tyre Recycling Systems operates at room temperature. It can achieve tire crushing, tire wire separation, fiber separation, and tire powder making at one time. During the process, no wastewater, waste gas, or dust is generated, which meets environmental protection requirements.

It can produce fine rubber powder below 30 meshes. The size of the rubber powder can be customized into different meshes according to demand. After the rubber powder is restored, it can replace natural rubber to make thousands of rubber products.

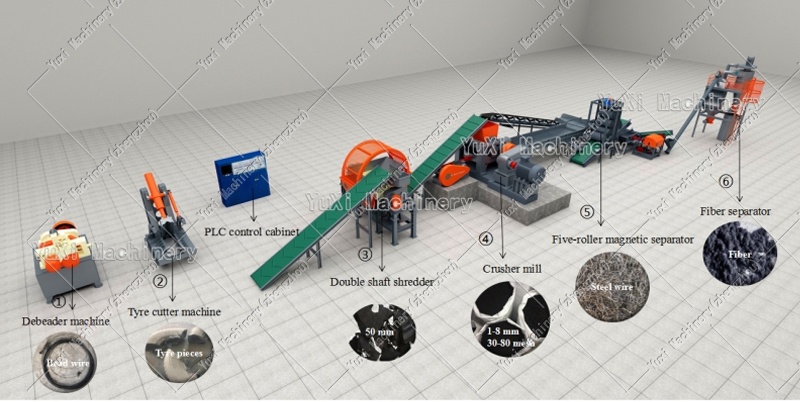

Process Flow

- Debeader: Remove the tyre rim steel wire

- Tyre Cutting Machine:Cut the whole tyre into 2-3 pieces

- Primary shredder machine: Final product size will be around 5cm

- Double roller breaker crushing machine: Final product size will be rubber granular(1-6mm) and rubber powder(10-80mesh)

- Five Roller magnetic separator machine: 96% tyre tread steel wire will be removal

- Fiber collection system: Collect the fiber

- Rubber Grinding machine- Final product size 20-120 mesh

Applications

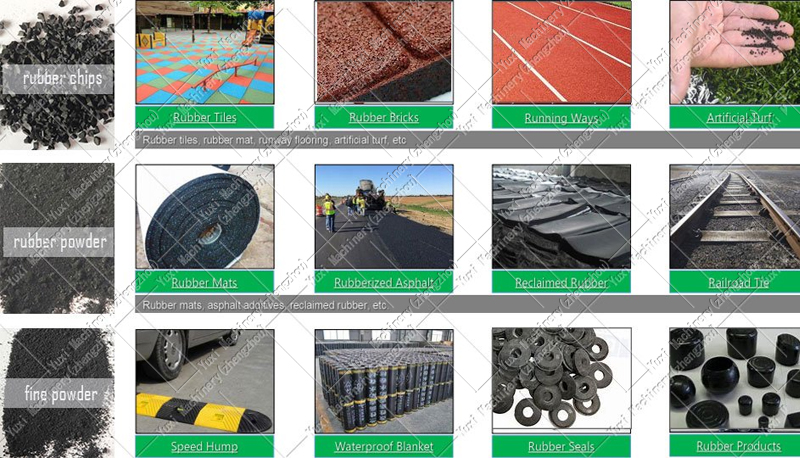

– 50mm rubber blocks can be sold to cement plants, paper mills and power stations to replace coal as fuel ;

– Rubber particles can be used as rubber floor tiles, rubber floor mats, park pavement, and kindergarten road pavement ;

– Rubber powder can be used for making new tires, paving asphalt on roads, insoles, sealing fillers, etc ;

Products Parameter

| No. | Name | Quantity | Motor |

| 1 | Tire Debeader | 1 set | 7.5kw |

| 2 | Tire Cutter | 1 set | 7.5kw |

| 3 | Tire Shredder | 1 set | 2*22+3 kW |

| 4 | Rubber Crushing Mill | 1 set | 132kw |

| 5 | Conveyor Equipment | 3 set | 2.2kw |

| 6 | Magnet Separator | 2 set | 1.1KW+2.2KW |

| 7 | Shaking Screen | 2 set | 3kw |

| 8 | Fiber Separator | 1 set | 11kw |

Features

- Rollers are made of chilled cast iron ,which are abrasion resistant with long service life.

- Rear roller is equipped with distance adjustment device,easy operation and convenience,turn the turbine to adjust the distance.

- Double roller material : Cast steel material

- Water cooling system to increase the using life of transmission parts