Tire Derived Fuel (TDF) Shredder Systems

What is Tire Derived Fuel (TDF) Shredder Systems

As a professional manufacturer of waste tire recycling equipment, Yuxi is committed to providing customers with efficient, stable, and intelligent complete line solutions. Tire-derived fuel (TDF) is a high-calorific value fuel with uniform particle size obtained by crushing and sorting waste tires. It is widely used in cement plants, power plants, paper mills, industrial boilers, and other fields.

Process Flow

- Tire debeader:Remove the tyre rim steel wire.

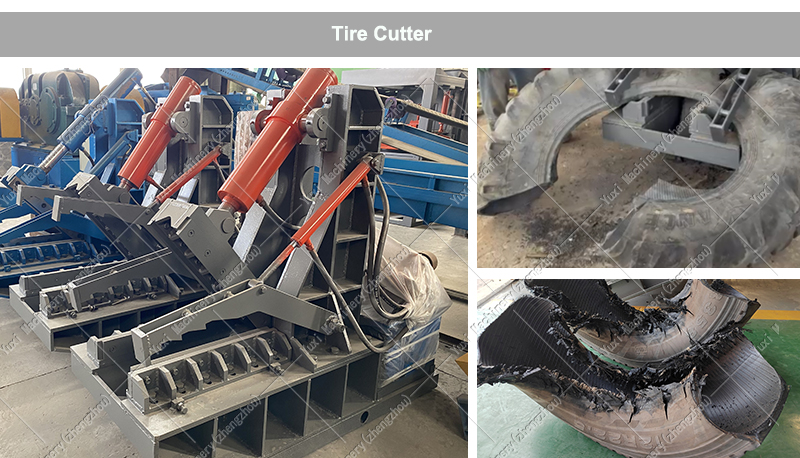

- Tire cutter: The cutting machine cuts the whole tire into uniform-sized rubber blocks.

- Conveying equipment: conveyor belt, screw conveyor and air pressure transmission system.

- Primary shredder machine: Final product size will be around 5cm.

Tire Derived Fuel (TDF) Shredder Video

Applications

Applicable materials: Passenger car tires, truck tires, engineering machinery tires, etc.

Finished product specifications: 50-80mm (adjustable according to demand)

Application:Cement kiln co-processing, rubber power plants, industrial boiler alternative fuels

Machine Details

1.TIRE DEBEADER

Yuxi tire debeader is specially designed for debeading tires and taking out the wire cord from tires before shredding.

2.TIRE CUTTING MACHINE

Yuxi tire cutter is able to cut giant tires into chunks as pre-cut for your tire shredding plant.

3.TIRE SHREDDING MACHINE

Yuxi tire shredder shreds waste tires into 50*50 mm or larger rubber blocks for easy subsequent machine processing.

Feature

1.Fully Automated: Car & Truck tire(debeaded) auto-feed system with conveyor belt integration. PLC control panel for real-time monitoring and adjustments.

2.Safety First: Emergency stop buttons, overload protection, and blade lock mechanisms.

3.Dual Outputs: Produce 30-50mm TDF

4.Less Downtime: Replaceable blades with 2000+ hour lifespan

5.High Efficiency: Process 2-20tons/hour of mixed car/truck tires.