Tire Rubber Granule Recycling Systems

What is Tire Rubber Granule Recycling Systems

Yuxi Tire Rubber Granule Recycling Systems is proven to convert wire-free rubber mulch into high quality, uncontaminated crumb rubber, steel and fiber. It’s a physically processing system, working in the normal temperature, causing no secondary pollution.

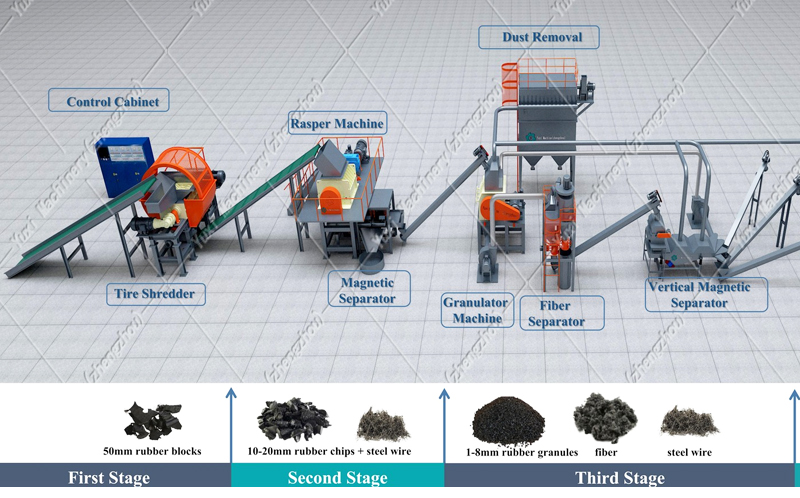

Process Flow

First stage: Primary shredder machine

– America Brand H13 & Japan Brand SKD11 Blade available

– China Top Two brand Zhejiang Tongli Planetary Reducer & Shanghai Boneng Reducer

– Humanized and customized design: Hollowed out ladder Increase friction and antiskid and operating platform in convenient after-sale inspetion and maintenance

Second stage: Steel wire separator machine

– America Brand D2 and Japan DC53 blade available

– China Top 2 Shanghai Boneng Reducer

– Automatic hydraulic opening and closing system in convenient after-sale inspetion and maintenance of the blade and working chamber

Third Stage: Rubber Granular machine

– America Brand D2 and Japan DC53 blade available

– China Top 2 Brand motor: Siemens And SIMO Motor available

– Automatic hydraulic opening and closing system in convenient after-sale inspetion and maintenance of the blade and working chamber

Tire Rubber Granule Recycling Video

Applications

Applicable materials: Passenger car tires, truck tires, engineering machinery tires, etc.

Finished product specifications: Rubber Mulch 10-20mm(Steel Wire Separated, Rubber Granulate 1-8mm(Fiber Separated)

Application:Playground ground, gardening and green areas, or be used as fuel

Gardens and exteriors, Athletics surfaces, Synthetic soccer field, Play areas, Modified asphalt, Molded products.

Machine Details

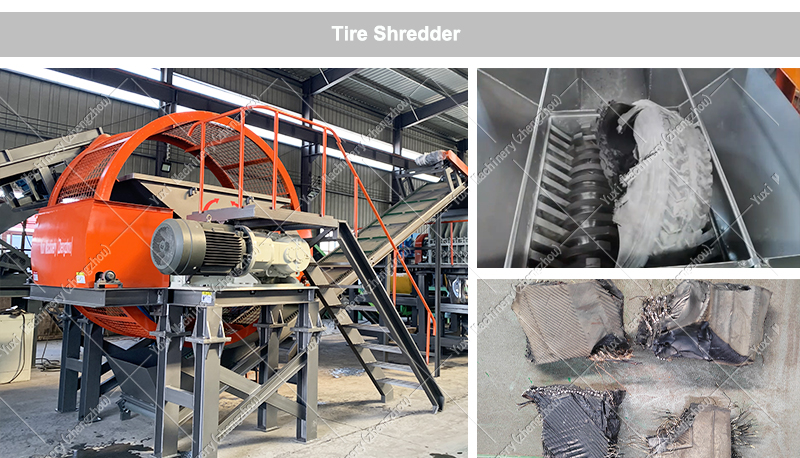

1.Tire Shredder

Yuxi double shaft shredder is specially designed for tire chips size separation. The shredded chips from prime shredder will drop on the rotary screen, and small chips will fall on the conveying belt, the big chips will be feed in the shredder for shredding and recycling again. The final chips will be around 50~60mm.

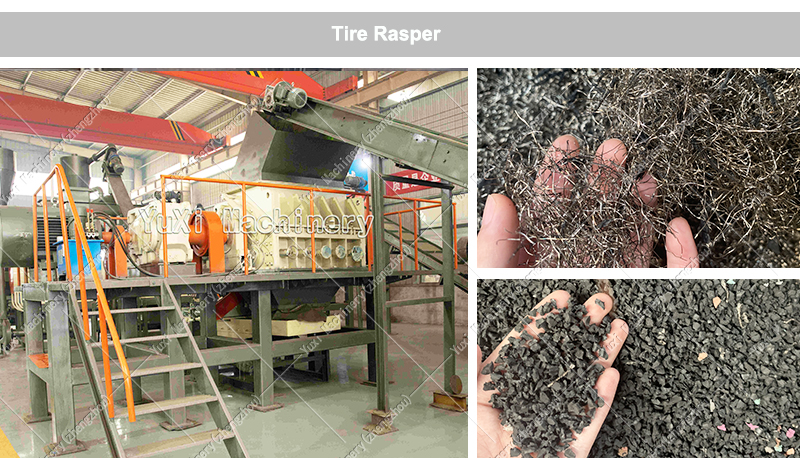

2.Tire Rasper

Yuxi rasper is used as the secondary shredder for primary size reduction of pre shredded chips, its patented design allows it to separate the wire from rubber tires in the purest, cleanest form possible, allowing processors to generate revenue streams from both rubber and wire.

3.Tire Rubber Granulator

Yuxi Rubber Granulator is the third step in the whole tire recycling process. At this step, wire free mulch is processed from rasper into the granulator, which grinds further into 1-5mm granules. The granules are re-screened and re-circulated until the desired size is reached. During the crumb rubber granulation process, 99.9% of the fiber is removed.

Why Choose Yuxi Tire Rubber Granule Recycling Systems

Rubber granules of different specifications can be produced and customized according to customer needs. The production line uses physical methods to operate at room temperature and will not produce secondary pollution.

Due to the different types and sizes of tires, the machines used in the tire recycling production line will also be different. But no matter car tires, truck tires, tractor tires, trailer tires, off road tires (OTR) and other types tires, yuxi can always provide you with the most suitable solution.