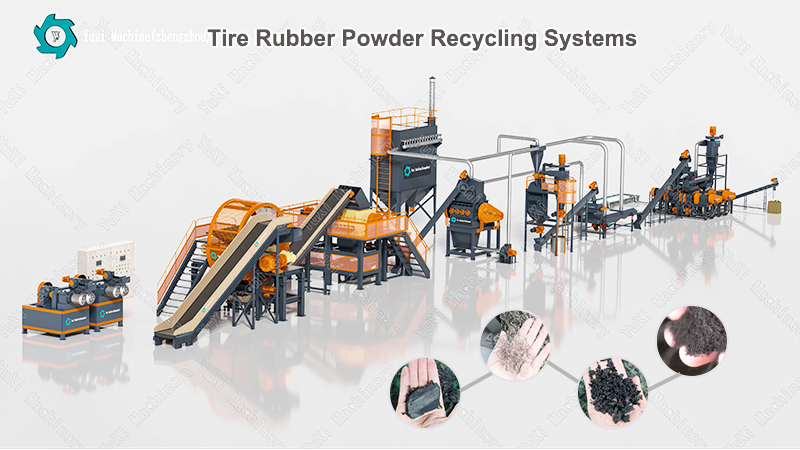

Tire Rubber Powder Recycling Systems

What is Tire Rubber Powder Recycling Systems

Tire rubber powder recycling systems use shredders, granulators, and miller machines to reduce waste tires into finely ground rubber powder, separating steel and fiber. The process involves cutting whole tires into blocks, then smaller granules, and finally grinding the granules into a powder with sizes ranging from 10-120 mesh. The resulting clean rubber powder is a valuable material for applications such as modified asphalt, rubber products, and coatings.

Process Flow

For different tire characteristics and productivity requirements, the production line structure may include:

- Automatic wire drawing machine: remove tire rims

- Conveying equipment: conveyor belt, screw conveyor and air pressure transmission system

- Shredding machine: tear the tire into film (50mm-150mm)

- Steel wire separator: separate rubber and steel wire, and process into colloidal particles (10mm-20mm)

- magnetic separator: from the rubber steel wire mixture of steel wire sorting

- Crusher: Pulverize colloidal particles to smaller size (1mm-8mm)

- Vibrating screen: the rubber particles of different sizes are sorted, and the oversized particles are sent back to the crusher for secondary crushing

- Fiber separator: remove foreign matter and fiber

- Secondary magnetic separator: remove the remaining fine steel wire

- Rubber Mill: Grind particles into powder

Tire Rubber Powder Recycling Video

Applications

Applicable materials: Passenger car tires, truck tires, engineering machinery tires, etc.

Finished product specifications: Rubber Powder 10-140mesh(adjustable according to demand)

Application:Molded products, roof coating, waterproofing and sealants, thermoplastic applications, modified asphalt and geo membranes

Machine Details

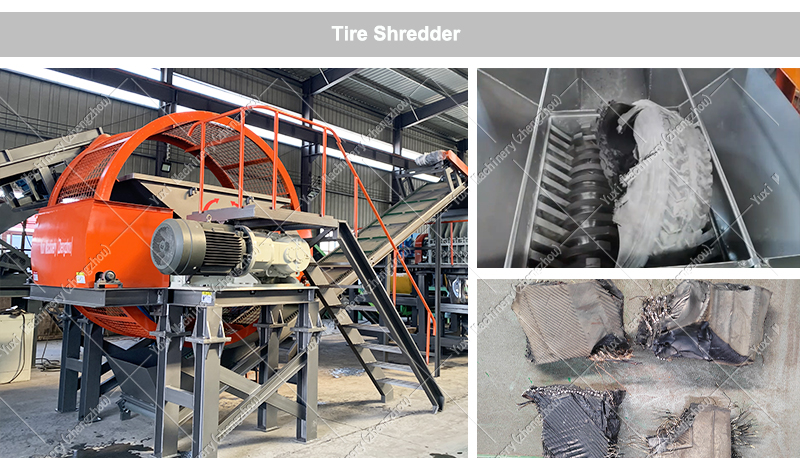

1.Double Shaft Shredder

YUXI double shaft shredder is specially designed for tire chips size separation. The shredded chips from prime shredder will drop on the rotary screen, and small chips will fall on the conveying belt, the big chips will be feed in the shredder for shredding and recycling again. The final chips will be around 50~60mm.

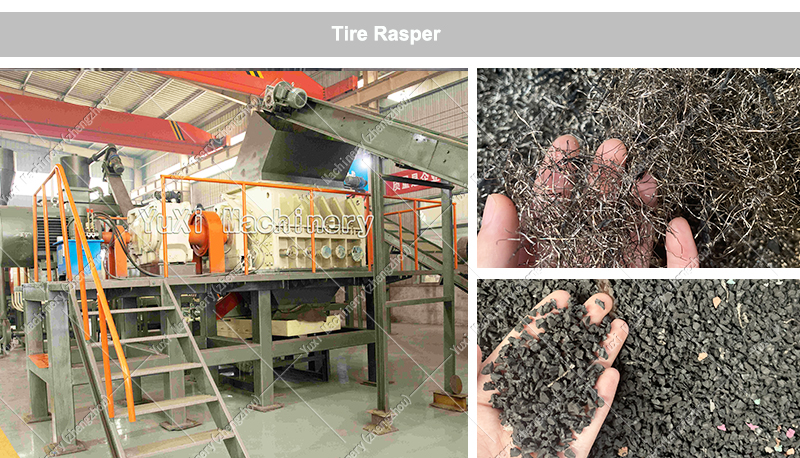

2. Tire Rasper

This system produces up to a 99% wire free chip ranging in size between 12-25mm depending on the desired size.After processing,the steel is removed by our magnetic separation system.At this point,the wire free rubber chips are ready to be colored and used for landscaping mulch and the steel is ready to be baled and sold to smelters.

3.Tire Rubber Granulator

Granulator Waste Tire Recycling Rubber Granule Making Machine is adopting physical recycling method and is designed to grind the rubber mulch from the rasper into small granules as fine as 1-6mm. The granules are screened and re-circulated until the desired size is reached.

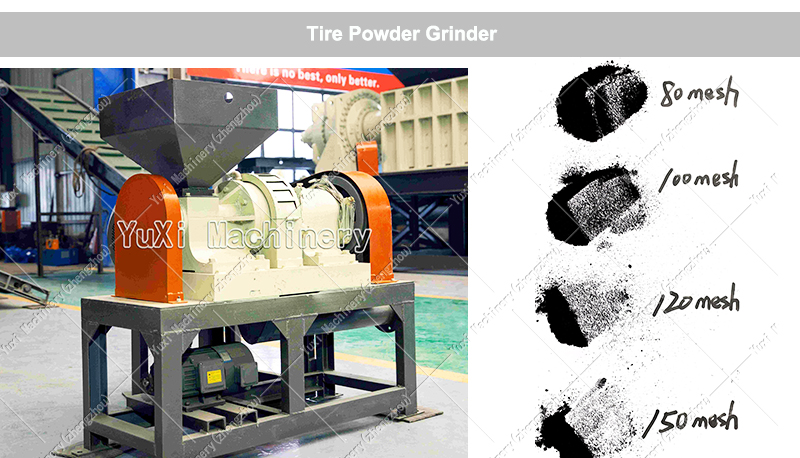

4. Tire Rubber Powder Pulverizer

Yuxi tire rubber pulverizer is designed to grind 1-6mm rubber granules from rubber granulators to 30-120 mesh fine rubber powder according to demand. It features with convenient operation, high speed grinding disc which makes a continuous operation.

Features

- The whole tire is directly put in, without breaking and pulling the steel ring in advance

- From the whole tire to 10-120mesh rubber powder, the whole process of production and packaging, without secondary handling intermediate links

- The maximum processing capacity is 10000kg/h, and only 7 people at most can complete all on-site operations

- Configure the device model based on the customer’s production requirements, ranging from 500kg/h to 10000kg/h

- Full combination of two-layer structure, make installation, replacement and maintenance more convenient and safer

- Seamless connection, the whole process of dust and smoke monitoring

- Adhere to the feeding experiment 80-100 hours before leaving the factory to ensure stable performance