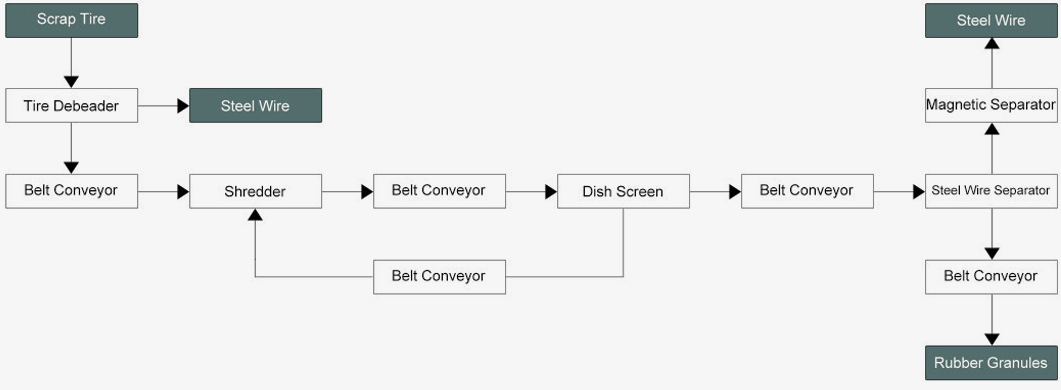

The scrap tire recycling production line is a comprehensive processing system that integrates automation, mechanization, and intelligence. It uses a series of specialized equipment to crush, separate, and grind the entire scrap tire, ultimately yielding high-purity rubber particles/powder, steel wire, fiber, and other renewable resources.

tire recycling line

Application of Waste Tire Recycling Machine

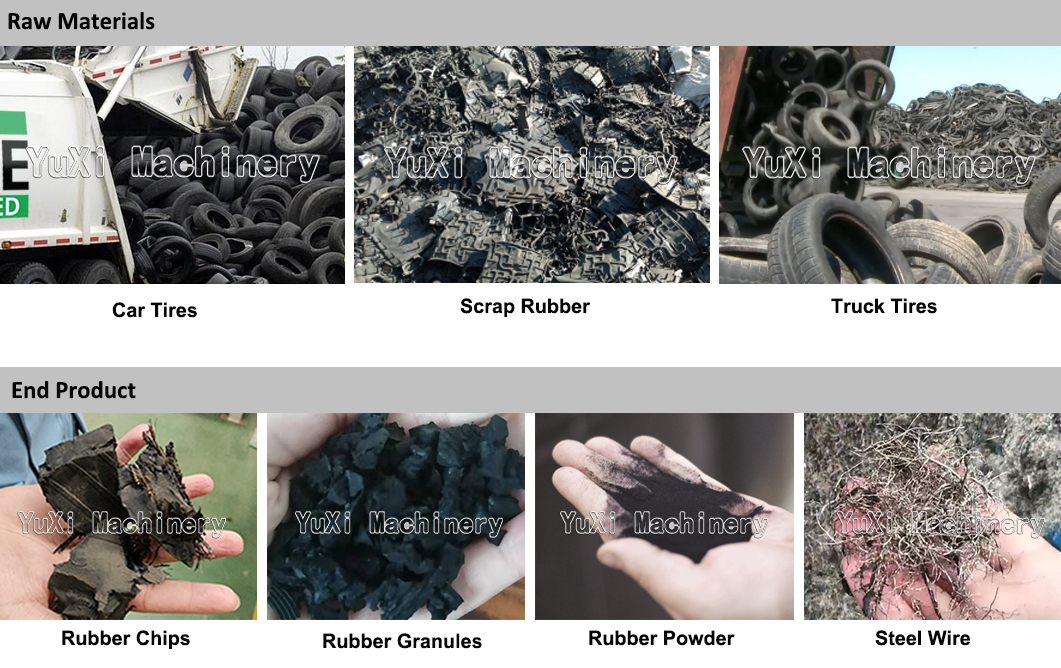

Raw materials: Scrap car tires, truck tires and other waste rubber product. Recycled tires have a wide range of uses and a broad market. Based on our understanding of the market, we can consider the following buyer channels:

- Steel mills companies

- Cement plants

- Chemical manufacturers

- Tire manufacturers

- Shoe and flip-flop manufacturers

- Asphalt production companies

Yuxi Machinery offers waste tire recycling equipment for sale

We offer customized, optimal tire recycling equipment at affordable prices, tailored to your production capacity and product size. Whether recycling rubber pellets or rubber powder, we can meet all your needs.

Feature of Tire Recycling Machine

- Physical shearing crushing is adopted, which can be carried out at normal temperature and without pollution.

- We can produce from 500kg/h-10000kg/h of tire recycling line, currently only top companies in China can reach this level.

- Our machines are in line with European environmental standards has been exported to France, Italy, Poland, and other countries.

- We have been working with SKF, Siemens, Schneider ABB and so on famous brand for 20 years.

Tire Cutting Machine

-

Tire cutting machine is specially designed for cut waste whole tire into small chunks , can cut 4 meter mining OTR tires into tire blocks.

Tire Drawing Machine

-

Tire drawing machine is specially designed for debeading tires and taking out the wire cord from tyres before shredding.

Tire Shredding Machine

-

Tire shredding machine is designed to turn whole tires into rough shreds chips around 50-100MM, which is used as a coal additive for industrial boilers.