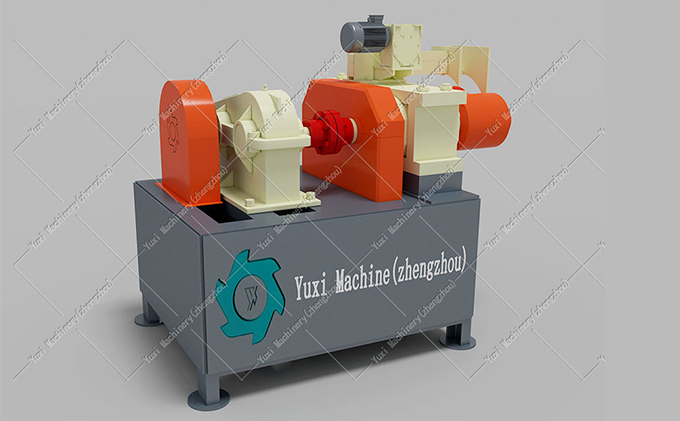

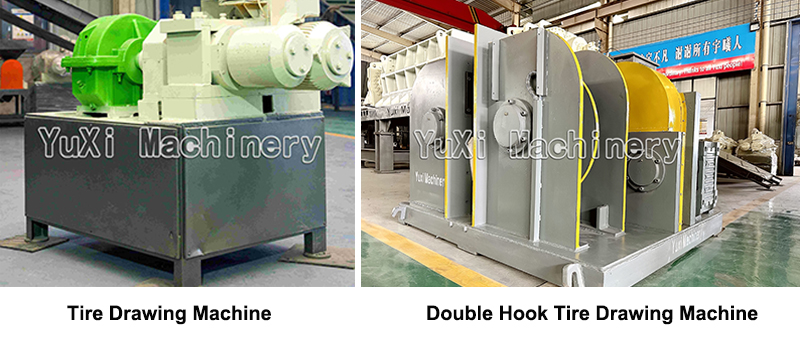

What is Tire Drawing Machine ?

The waste tire wire drawing machine adopts advanced physical separation technology, which can automatically separate the steel wire and rubber/fiber from the entire waste tire thoroughly and cleanly.

Working Principle

The wire drawing machine operates based on purely mechanical principles. Its core technology utilizes a sophisticated combination of cutting tools and a pulling mechanism to precisely cut, peel, and pull the pre-treated tire bead (bead portion). By leveraging the differing physical properties of steel wire and rubber, the bond between them is broken, allowing the complete wire bead to be extracted from the tire intact.

Tire Drawing Machine Video

Raw Material&Final Product

Main Applications:Separates steel wire from waste tires

Raw Materials:Passenger car tires, truck tires (excluding OTR tires)

Main Final Products:Clean scrap steel wire (directly recyclable or salable), separated rubber tire.

Feature

- Utilizes a PLC intelligent control system with one-touch start and stop, resulting in a high degree of automation.

- High processing efficiency: A single unit can process dozens of tons of scrap tires daily.

- High separation purity, maximizing value.

- Core components such as cutting tools, hydraulic systems, and bearings are all imported or custom-made from specialized materials, offering wear and impact resistance and a long service life.

- Modular design allows for simple and quick maintenance and replacement of key components, ensuring maximum production continuity.

- Low energy consumption helps customers reduce operating costs.

We can provide customized solutions for single machines or complete production lines based on the customer’s raw material characteristics, production requirements and site conditions.