What is Tire Shredding Machine?

Our scrap tire shredding machine is a high-performance, durable shredder designed by our company based on years of technological research and development, specifically for processing all types of scrap passenger car, truck, and radial tires.

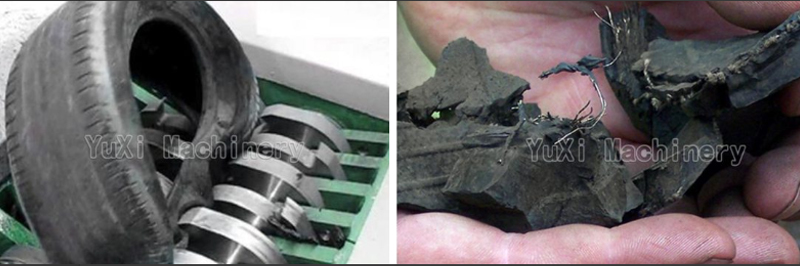

It utilizes a heavy-duty cutterhead structure and a high-torque power system to easily shred entire tires into uniformly sized rubber chunks, effectively separating rubber, steel strands, and fibers. It is the core primary shredder in a scrap tire recycling line.

Working Principle

The equipment operates on a dual-shaft shearing principle. A power system drives two heavy-duty shafts equipped with staggered blades, rotating at a relatively low speed and high torque. Material is fed into the shredder chamber through a feed system. The rotating blades grab, tear, squeeze, and shear the material, pulverizing it into small pieces under the powerful shear force. Material smaller than the screen aperture falls through and is discharged by a discharge conveyor or screw conveyor. Material larger than the aperture remains in the chamber and is continuously torn by the blades until it reaches the required size and is discharged.

Raw Material&Final Product

Raw material

All kinds of tires: Normal Car Tires, Truck Tires, OTR Tires, Engineering Car Tires.

Final Product

50mm – 100mm rubber block.

The shredder produces irregular lumps. The output size can be controlled by adjusting the blade gap and screen aperture to meet the customer’s subsequent process requirements.

Tire Shredding Machine Video

Feature of Tire Shredder

Highly durable

Made of national standard steel and special alloy cutters, and undergoing a special heat treatment process, the machine boasts strong wear resistance and a long service life.

Low failure rate

Heavy-duty bearings and a high-torque gearbox ensure stable operation under heavy loads with minimal failure.

PLC electronic control system

Equipped with a PLC electronic control system, it offers one-touch start/stop, overload protection, and automatic reverse, ensuring simple operation and safety. When encountering unbreakable objects or an overload, the machine automatically reverses to remove foreign objects, protecting the core components.

Low energy consumption

The low-speed, high-torque design reduces energy consumption compared to traditional crushing equipment.

Environmentally friendly design

The entire machine is sealed, with an optional dust suppression system, effectively controlling dust pollution and meeting environmental requirements.

Easy to clean

The housing is easily accessible for cleaning and maintenance.

Technical Parameters

| Shredder with Trommel | YX1300S | YX1200S | YX1000S | YX800S |

| Power | 45kw*2 | 45Kw*2 | 37kw*2 | 22kw*2 |

| Voltage | as per request | |||

| Cutting Chamber L*W | 1304*920mm | 1204*920mm | 1004*680mm | 804*680mm |

| Blade Diameter | 450mm | 450mm | 450mm | 450mm |

| Equipment Dimensions L*W*H(mm) | 5120*3010*4100 | 5010*3010*4100 | 3800*3010*3100 | 3350*3010*3050 |

| Equipment Weight | 18500kg | 16500Kg | 7000kg | 5700kg |

| Hopper Opening L*W*H(mm) | 2050*1650*1000 | 1850*1650*900 | 1300*1400*700 | 1150*1300*800 |

| Final Product | 50mm | 50mm | 50mm | 50mm |

Customized machine

We can provide customized solutions for single machines or complete production lines based on the customer’s raw material characteristics, production requirements and site conditions.